UNIONS

Home / Forged Fitttings / UNIONS

FORGED FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

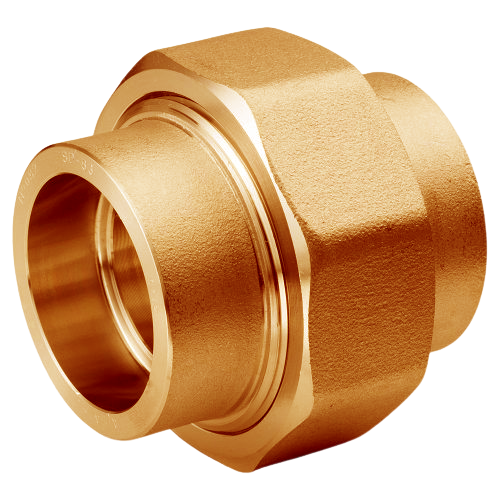

COPPER NICKEL UNIONS forged fittings

Copper-nickel Unions by Nexus Alloys and Steels are a type of forged fitting widely used in various industries due to their excellent properties. The copper component provides excellent thermal conductivity and corrosion resistance, while the nickel component adds strength and durability. This makes copper-nickel Unions ideal for applications that require high strength and resistance to corrosion, such as in the marine, oil & gas, and chemical industries

DESCRIPTION

A union is a type of fitting that allows two pipes to be joined together in a manner that facilitates easy disconnection and reconnection without the need for cutting. Forged fittings, including Unions, are manufactured using a forging process that involves heating a piece of metal, then hammering or pressing it into the desired shape. This process increases the strength and reliability of the fitting

Key Features of Copper-Nickel Union

- Material : They are made from a copper-nickel alloy, which provides excellent resistance to corrosion, especially in marine environments

- Durability : The forging process used to manufacture these Unions ensures high durability and the ability to withstand extreme pressures and temperatures

- Versatility : CuNi Unions are used in a variety of industries, including shipbuilding, desalination plants, and offshore oil and gas platforms

- Sizes and Configurations : These Unions are available in a range of sizes and configurations to meet different piping requirements

- Performance : They offer superior performance in challenging conditions, making them an ideal choice for industries seeking efficient and long-lasting piping solutions

GRADES

- Copper Nickel 90/10 (C70600) : This grade contains 90% copper and 10% nickel along with small amounts of iron and manganese to improve corrosion resistance

- Copper Nickel 70/30 (C71500) : This grade contains 70% copper and 30% nickel along with small amounts of iron and manganese. It offers even better resistance to corrosion and is used in more demanding applications

TECHNICAL SPECIFICATION

- Material : Copper-Nickel alloy, often in grades such as 90/10 (C70600) or 70/30 (C71500), depending on the specific requirements of the application

- Sizes : CuNi Unions are available in a range of sizes to suit different piping requirements. Common sizes can range from 1/8" to 4"

- Pressure Ratings : These Unions are designed to withstand high pressures. The pressure rating can vary based on the size and design of the union, but they are often suitable for high-pressure applications

- Temperature Ratings : CuNi Unions can operate effectively within a wide temperature range, making them suitable for applications with varying temperature requirements

- Standards : CuNi Unions are often manufactured according to international standards such as ASME, ASTM, ANSI, etc., to ensure quality and compatibility

- End Connections : These Unions can be designed for various end connections, such as threaded, socket weld, depending on the installation requirements

- Corrosion Resistance : Due to the copper-nickel alloy, these Unions have excellent resistance to corrosion, especially in marine environments

SERVICES & CERTIFICATES

- Testing Facility Available Our wide range of quality assurance procedures includes Radiography tests, Chemical Analysis, Mechanical Tests, Ultrasonic tests, PMI tests, Hydrostatic tests, Corrosion tests, Metallography Tests, and Miscellaneous tests

- Test Certificates : Demonstrating our dedication to quality, our Test Certificates adhere to EN 10204 type 3.1 and 3.2 standards. Additionally, our certificates integrate NABL laboratory test reports, ensuring the utmost quality standards in our products