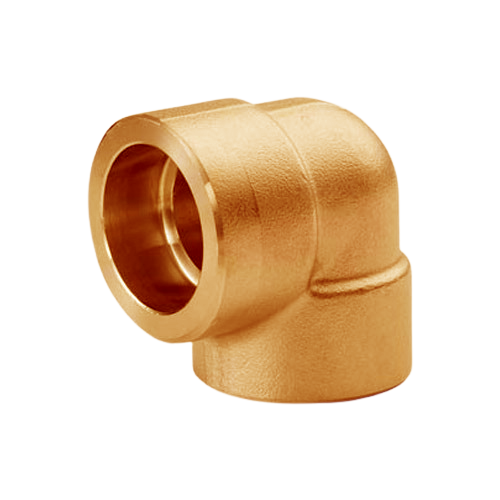

90 DEGREE ELBOW

Home / Forged Fitttings / 90 DEGREE ELBOW

Forged Fittings

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

COPPER NICKEL 90 FORGED DEGREE ELBOW

Nexus Alloys & Steels is a well-known manufacturer and exporter of Copper Nickel 90 Degree Elbows. These pipe fittings play a crucial role in changing the direction of pipes by 90 degrees. Our top-notch product allows for the rotation of pipes in either direction, ensuring a strong and long-lasting welded connection. We offer two variations of the Copper Nickel 90 Degree Elbow: the Long Radius Elbow and the Short Radius Elbow, both meticulously designed to meet international standards

DESCRIPTION

A 90-degree elbow forged fitting is a type of pipe fitting used to connect two pipes at a right angle (90 degrees). It is designed to change the direction of flow in a piping system and is commonly used in various industries such as oil and gas, petrochemical, chemical processing, power generation, and more. At Nexus Alloys & Steels, we take great pride in being a leading manufacturer and exporter of Copper Nickel 90 Degree Elbows. As a customer-centric company, we understand that each client has unique requirements. Therefore, we offer flexibility in terms of class/working pressure and material for the Copper Nickel 90 Degree Elbows, ensuring tailored solutions that precisely meet their needs

GRADES

- Cu-Ni 90/10 (UNS C70600) 90 Degree Elbows : Manufactured from copper-nickel alloy 90/10, these elbows offer excellent corrosion resistance in marine environments. Ideal for piping systems, ensuring durability and reliability

- Cu-Ni 70/30 (UNS C71500) 90 Degree Elbows : Crafted from copper-nickel alloy 70/30, these elbows provide superior corrosion resistance and thermal stability. Suitable for diverse applications, guaranteeing robust performance in demanding conditions

TECHNICAL SPECIFICATION

- ASTM Standard : ASTM B111 ASME SB111 / ASTM B466 ASME SB466 / ASTM B 467 ASME SB467 / ASTM B543, B552 ASME SB543 SB552,ASTM B151, ASME B16.11 & BS 3799

- Range : 1/2" to 4" - 3000#, 6000# in ASME B16.11 & EEMU standard

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports