INSERTS

Home / Forged Fittings / INSERTS

FORGED FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

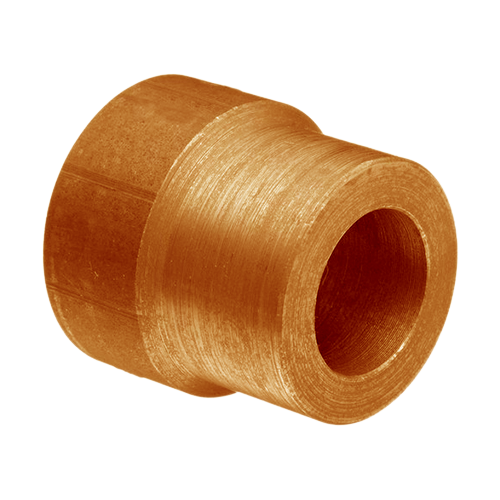

COPPER NICKEL INSERTS

The Copper-Nickel Forged Fitting Inserts by Nexus Alloys and Steels are high-quality fittings primarily used in plumbing and industrial applications. They are made from a copper-nickel alloy, known for its excellent resistance to corrosion, especially in marine environments. These Inserts are forged, a process that involves heating the alloy until it’s malleable and then hammering or pressing it into the desired shape. This process increases the strength and durability of the fittings, making them suitable for high-pressure applications

DESCRIPTION

The Inserts from Nexus Alloys and Steels are designed to fit inside a larger component, providing a secure, leak-proof connection. They come in various sizes and shapes to accommodate different types of pipes and tubes. Overall, Copper-Nickel Forged Fitting Inserts manufactured by Nexus Alloys and Steels are a reliable and durable choice for any application that requires strong, corrosion-resistant connections

Key Features of Copper-Nickel Inserts

- Material : Made from a copper-nickel alloy, known for its excellent resistance to corrosion

- Forged for Strength : The forging process increases the strength and durability of the fittings, making them suitable for high-pressure applications

- Corrosion Resistance : Especially resistant to corrosion in marine environments, making them ideal for use in such conditions

- Versatility : Available in various sizes and shapes to accommodate different types of pipes and tubes

- Secure Connection : Designed to fit inside a larger component, providing a secure, leak-proof connection

- Durability : The strength of the copper-nickel alloy and the forging process make these inserts extremely durable, ensuring a long lifespan for the fittings

GRADES

- Copper Nickel 90/10 (C70600) : Comprising 90% copper and 10% nickel, this alloy incorporates minor quantities of iron and manganese, enhancing its strength and hardness. Exceptionally ductile, it can be formed into intricate shapes without the risk of cracking or breaking. The alloy exhibits elevated levels of strength and toughness, even under high temperatures. With a yield strength of 221 MPa and a tensile strength of 483 MPa, it attains an ultimate tensile strength of 760 MPa. Notably, the material's elongation at break is 40%, making it particularly suitable for applications involving high-stress conditions

- Cupro Nickel 70/30 (C71500) : Comprising 70% copper and 30% nickel, this alloy includes minor quantities of iron and manganese, augmenting its strength and corrosion resistance. The addition of nickel contributes to enhanced resistance against seawater corrosion and biofouling, rendering it well-suited for marine applications. With an ultimate tensile strength of 310 MPa and a yield strength of 110 MPa, it boasts an elongation at break of 40%, making it suitable for various forming and bending operations

TECHNICAL SPECIFICATION

- Dimensions : ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799

- Grades : Copper Nickel 90/10 (C70600), Cupro Nickel 70/30 (C71500)

- Size : 1/8" NB to 4" NB (Socketweld and Screwed-Threaded)

- Class : 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

- Type : Socketweld Fittings, Screwed-Threaded Fittings

SERVICES & CERTIFICATES

- Testing Facility Available : Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test, Hydrostatic test, Radiography test, Corrosion test, Metallography Test, Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 and 3.2 as well as NABL lab test reports