BUSHINGS

Home / Forged Fittings / BUSHINGS

FORGED FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

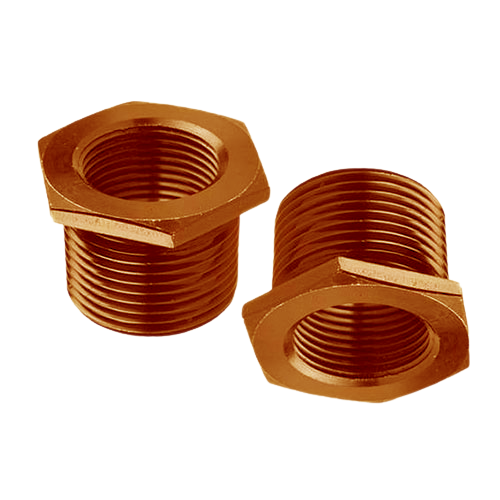

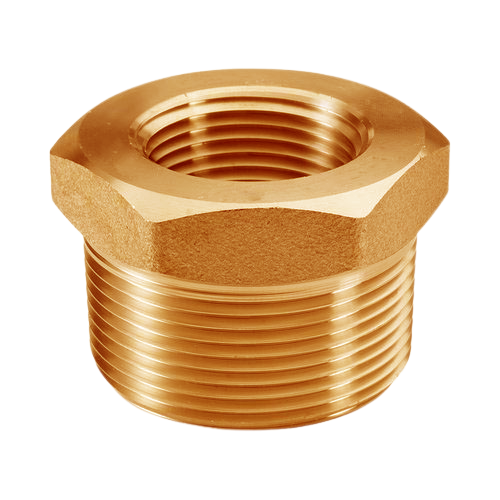

COPPER NICKEL BUSHINGS

Copper-nickel forged fitting Bushings from Nexus Alloys and Steels are made from a copper-nickel alloy, which combines the beneficial properties of both copper and nickel. This alloy is known for its excellent resistance to corrosion and erosion, especially in marine environments. The forging process involves heating the copper-nickel alloy until it’s malleable, then applying high pressure to shape it into the desired form. This process enhances the strength and durability of the Bushings. These Bushings by Nexus Alloys and Steels are used to connect different sections of a pipe or to adapt different sizes of pipes to each other. They provide a tight, leak-proof seal, ensuring the efficient and safe transport of fluids

DESCRIPTION

Copper-nickel forged fitting Bushings by Nexus Alloys and Steels typically have a hexagonal or octagonal outer shape for easy wrench grip. The interior is hollow and threaded to allow for secure attachment to pipes. Due to their robustness and resistance to corrosive elements, these Bushings are commonly used in industries such as shipbuilding, desalination plants, offshore, oil and gas platforms, and power generation

Key Features of Copper-nickel forged fitting Bushings

- Material : Made from a copper-nickel alloy, known for its excellent resistance to corrosion and erosion, especially in marine environments

- Forging Process : The bushings are forged, a process that enhances their strength and durability

- Function : They are used to connect different sections of a pipe or to adapt different sizes of pipes to each other, providing a tight, leak-proof seal

- Design : Typically have a hexagonal or octagonal outer shape for easy wrench grip. The interior is hollow and threaded for secure attachment to pipes

- Applications : Commonly used in industries such as shipbuilding, desalination plants, offshore oil and gas platforms, and power generation due to their robustness and resistance to corrosive elements

GRADES

- Copper Nickel 90/10 (C70600) : This grade is composed of 90% copper and 10% nickel. The remaining elements include iron and manganese, which are added to enhance the overall strength and corrosion resistance. This alloy is known for its excellent resistance to seawater corrosion, making it a popular choice for marine applications such as shipbuilding and offshore oil platforms

- Copper Nickel 70/30 (C71500) : This grade has a higher nickel content (30%) compared to Copper Nickel 90/10. The increased nickel content provides superior resistance to corrosion and erosion, especially in marine environments. This makes it an ideal choice for more demanding applications that require a higher level of corrosion resistance

TECHNICAL SPECIFICATION

- Standards : B16.11 and BS 3799

- Size : The size range for these bushings is from 1/8” NB to 4” NB

- Pressure Class : They are available in different pressure classes such as 2000 LBS, 3000 LBS, 6000 LBS, and 9000 LBS

- Type : Only threaded

- Grades : The common grades are Copper Nickel 90/10 (C70600), Copper Nickel 70/30 (C71500)

- Chemical Composition : The chemical composition of Copper Nickel 90/10 is approximately 88.7% Cu, 1.3% Fe, and 1.0% Ni

SERVICES & CERTIFICATES

- Testing Facility Available : Radiography test, Corrosion test, Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test, Hydrostatic test, Metallography Test, Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 and 3.2 as well as NABL lab test reports