TEE

Home / Forged Fitttings / TEE

Forged Fittings

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

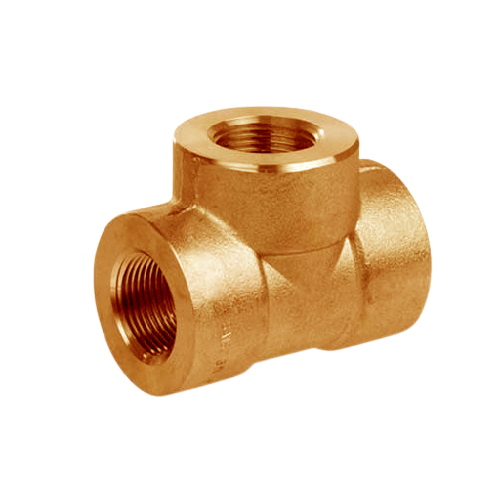

COPPER NICKEL FORGED TEE

Nexus Alloys and Steel is a well-known manufacturer and exporter of Forged Tee fittings. Our primary focus is on providing our clients with competitive prices for high-quality ASME B16.11 Forged Tee Fittings that are specifically designed to offer exceptional resistance to corrosion. Our Forged Threaded and Socket Weld Tee Fittings are crafted from premium raw materials, ensuring durability and a long service life. We offer two main types of products: Threaded/Socket Weld Equal Tee and Threaded/Socket Weld Unequal Tee, both featuring a T-shaped body with two open outlets

DESCRIPTION

A forged tee is a type of pipe fitting that plays a crucial role in plumbing and piping systems. It is designed to create a T-shaped junction, allowing for the diversion or combination of fluid flow in different directions. We take pride in being a leading manufacturer and exporter of Copper Nickel Forged Tee fittings. At Nexus Alloys and Steel, we strive to build strong and lasting relationships with our customers by consistently delivering top-notch products. With easy weldability, high tensile strength, as well as flexibility under elevated temperatures and pressures, these Forged Tees find a range of applications across various industries such as chemical processing, oil and gas, and petrochemical

GRADES

- Cu-Ni 90/10 (UNS C70600) Forged Tee : Precision-engineered from 90% copper and 10% nickel alloy, this tee ensures superior corrosion resistance, making it ideal for durable and reliable applications in various industries

- Cu-Ni 70/30 (UNS C71500) Forged Tee : Crafted from a copper-nickel alloy containing 70% copper and 30% nickel, this forged tee combines strength with corrosion resistance, providing longevity and reliability across diverse applications

TECHNICAL SPECIFICATION

- ASTM Standard : ASTM B111 ASME SB111 / ASTM B466 ASME SB466 / ASTM B 467 ASME SB467 / ASTM B543, B552 ASME SB543 SB552,ASTM B151, ASME B16.11 & BS 3799

- Range : 1/2" to 4" - 3000#, 6000# in ASME B16.11 & EEMU standard

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports