PLUGS

Home / Forged Fittings / PLUGS

FORGED FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

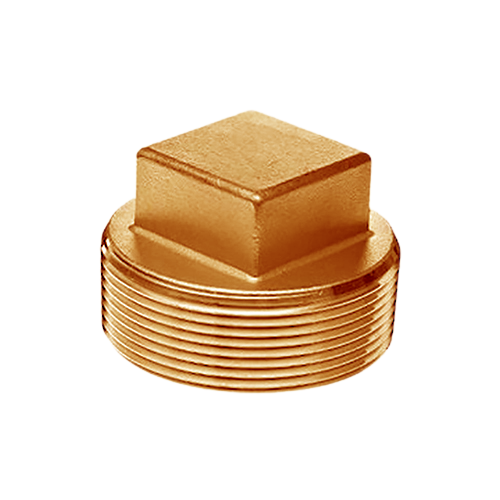

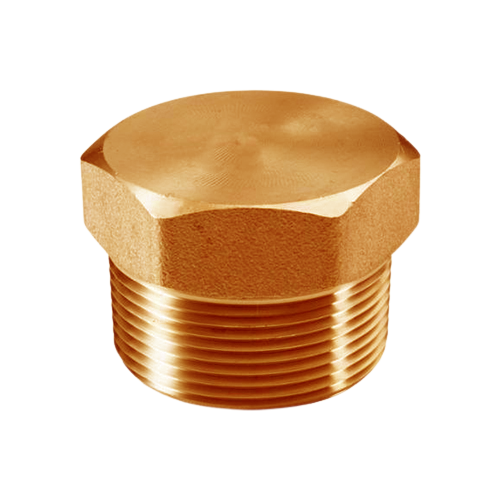

COPPER NICKEL PLUGS

Copper-Nickel Plugs from Nexus Alloys and Steels, often abbreviated as CuNi Plugs, are a type of forged fittings that play a crucial role in various industrial applications. These Plugs are crafted from a unique alloy that blends copper and nickel, imparting them with remarkable resistance to corrosion. This makes them particularly well-suited for use in marine environments. The manufacturing process, known as forging, involves heating the copper-nickel alloy until it becomes malleable, and then shaping it under high pressure. This ensures the Plugs are extremely durable and can withstand high pressures and temperatures

DESCRIPTION

Copper-Nickel Plugs from Nexus Alloys and Steels are commonly used in industries such as shipbuilding, desalination plants, and offshore oil and gas platforms, where they are exposed to harsh and corrosive conditions. They are available in a range of sizes and configurations, making them adaptable to various piping requirements. In summary, Copper-Nickel Plugs are a robust and reliable choice for demanding industrial applications. They offer a unique combination of durability, corrosion resistance, and versatility, making them an ideal choice for industries seeking efficient and long-lasting piping solutions. Their superior performance in challenging conditions underscores their value in the industrial sector

Key Features of Copper-Nickel Plugs (Forged Fittings)

- Corrosion Resistance : They are highly resistant to corrosion, which makes them ideal for use in marine and offshore environments. They are not easily affected by seawater, so they can last in salient environments for many years

- Thermal and Electrical Conductivity : Copper-nickel forged fittings have excellent thermal and electrical conductivity, making them ideal for use in heat exchangers and other applications

- High Strength and Durability : These fittings have good load-bearing capacity, high tensile strength, and excellent yield strengths. They are also known for their toughness and high ductility

- Versatility and Weldability : Copper-nickel Plugs are known for their excellent versatility and weldability

- Resistance to Cracking : One of the key features of these fittings is their resistance to cracking and failure under extreme pressure and temperature conditions

- Standards Compliance : They comply with various standards such as ASTM B122, B171, B466, B467, ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

- Various Grades Available : They are available in different grades like Copper Nickel 90/10 (C70600), Cupro Nickel 70/30 (C71500)

GRADES

- Copper Nickel 90/10 (C70600) : This variant is made up of 90% copper and 10% nickel, supplemented with minor quantities of iron and manganese to enhance its resistance to corrosion. Its superior resistance to seawater makes it a popular choice for marine applications

- Copper Nickel 70/30 (C71500) : This variant comprises 70% copper and 30% nickel, with traces of iron and manganese. It provides superior corrosion resistance and is utilized in applications that demand higher resilience

TECHNICAL SPECIFICATION

- Material : Copper Nickel Alloy (Cu-Ni 90/10 or Cu-Ni 70/30). The Cu-Ni 90/10 alloy has 90% copper and 10% nickel content

- Standards : BS 3799 and B16.11

- Types : Square, Round, Hex (only threaded)

- Size : 1/8” NB to 4” NB

- Class : 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

SERVICES & CERTIFICATES

- Testing Facilities : Radiography tests, Chemical Analysis, Mechanical Tests, Ultrasonic tests, PMI tests, Hydrostatic tests, Corrosion tests, Metallography Tests, and Miscellaneous tests

- Test Certificates : Test Certificates adhere to EN 10204 type 3.1 and 3.2 standards. Additionally, our certificates integrate NABL laboratory test reports, ensuring the utmost quality standards in our products