SWAGE NIPPLES

Home / Forged Fitttings / SWAGE NIPPLES

Forged Fittings

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

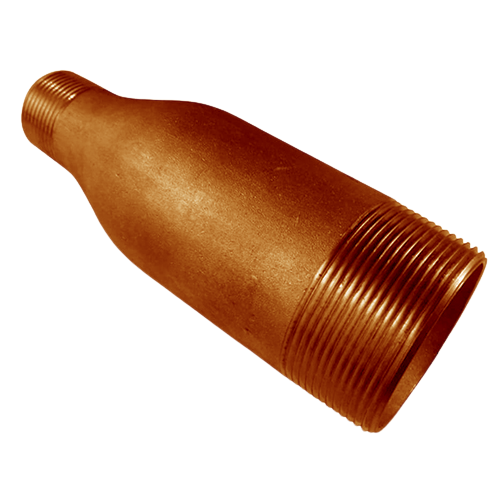

COPPER NICKEL FORGED SWAGE NIPPLES

Nexus Alloys and Steel is a reputable manufacturer and exporter of copper nickel forged Swage Nipples, specializing in producing a wide range of industrial products. Our priority lies in delivering high-quality Swage Nipples promptly, meeting various material, size, and specification requirements. By following client instructions and international quality standards, we ensure that our products, including the Forged Swage Nipple, demonstrate superior quality, impeccable finish, and efficient functionality. Before dispatching our products to customers, we conduct rigorous testing to assess their physical properties, mechanical performance, chemical composition as well as their ability to perform in various environments

DESCRIPTION

A forged swage nipple is a specialized pipe fitting used in piping systems to connect two pipes of different sizes. It is a short piece of pipe with male-threaded ends, and it is commonly used to reduce the diameter of a pipe run. The term "swage" refers to the process of gradually reducing the diameter of the pipe. As a leading manufacturer of copper nickel forged swage nipple, we place great importance on quality, precision, and innovation by employing cutting-edge methods and technology. Our advanced manufacturing facility allows for continuous production of top-notch products

GRADES

- Cu-Ni 90/10 (UNS C70600) Forged Swage Nipple : Crafted from a copper-nickel alloy with 90% copper and 10% nickel, this swage nipple offers outstanding corrosion resistance, ideal for a variety of industrial applications

- Cu-Ni 70/30 (UNS C71500) Forged Swage Nipple : Made from a copper-nickel alloy with 70% copper and 30% nickel, this forged swage nipple combines strength and corrosion resistance, ensuring durability in diverse industrial settings

TECHNICAL SPECIFICATION

- ASTM Standard : ASTM B111 ASME SB111 / ASTM B466 ASME SB466 / ASTM B 467 ASME SB467 / ASTM B543, B552 ASME SB543 SB552,ASTM B151

- Range : 1/2" to 4" - 3000#, 6000# in MSS-SP-95 & EEMU standard

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports