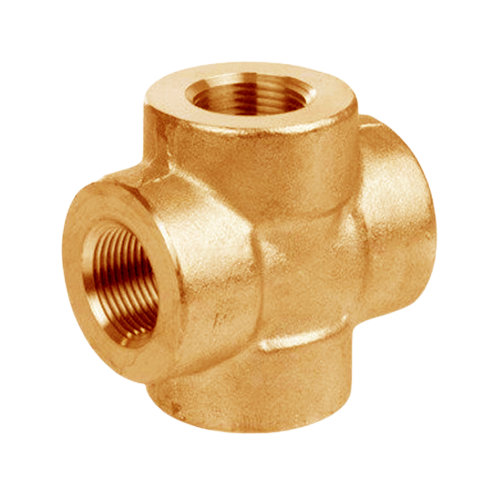

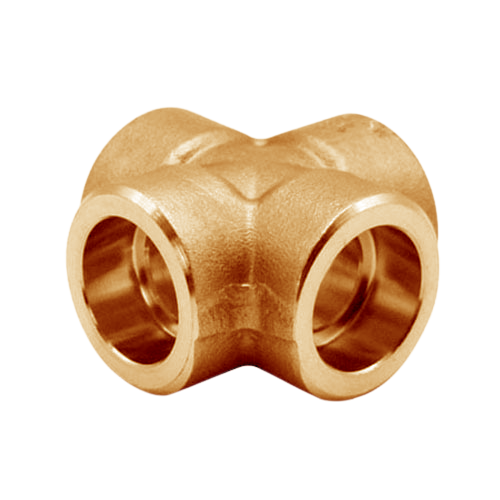

CROSS

Home / Forged Fittings / CROSS

FORGED FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

COPPER NICKEL CROSS FORGED fittings

Nexus Alloys and Steels, a leading manufacturer and exporter based in Mumbai, India, offers a range of high-quality products. Among the offerings is the Copper Nickel (Cu-Ni) Forged Cross, a product that stands out for its exceptional resistance to corrosion. Precision-crafted, these fittings demonstrate outstanding durability and performance, capable of withstanding both high temperatures and extreme cold conditions

DESCRIPTION

The Cu-Ni Forged Cross fittings consist of 10% Nickel, 1.4% Iron, and 0.80% Manganese. This distinctive blend guarantees exceptional corrosion resistance, especially in demanding marine environments. Additionally, these fittings offer dependable safeguarding for Copper-Nickel pipe flanges against non-oxidizing acids present in organic compounds, brine water, saltwater, and diluted hazardous acids. These Cu-Ni Forged Cross fittings are ideal for use in various industries including marine and shipbuilding, oil and gas, power generation, chemical processing, mineral and metallurgical projects, and desalination plants

Key Features of Copper-Nickel Cross

- Material : They are made from a copper-nickel alloy, which provides excellent resistance to corrosion, especially in marine environments

- Durability : The forging process used to manufacture these crosses ensures high durability and the ability to withstand extreme pressures and temperatures

- Versatility : CuNi Crosses are used in a variety of industries, including shipbuilding, desalination plants, and offshore oil and gas platforms

- Sizes and Configurations : These crosses are available in a range of sizes and configurations to meet different piping requirements

- Performance : They offer superior performance in challenging conditions, making them an ideal choice for industries seeking efficient and long-lasting piping solutions

GRADES

- Copper Nickel 90/10 (Cu-Ni 90/10) : This alloy, also known as UNS C70600, is composed of 90% copper and 10% nickel. It offers excellent resistance to corrosion, particularly in marine environments. The alloy also contains small amounts of iron and manganese, which enhance its overall strength and corrosion resistance. It has good machinability and a melting point that makes it suitable for various applications

- Copper Nickel 70/30 (Cu-Ni 70/30) : Also known as UNS C71500, this alloy is composed of 70% copper and 30% nickel. It has a higher nickel content than Cu-Ni 90/10, providing even better resistance to corrosion and erosion. It also contains small amounts of manganese and iron, making it more resistant to erosion and corrosion. The alloy has an ultimate tensile strength of 310 N/mm², an elongation of 27%, and a hardness of 80-120

TECHNICAL SPECIFICATION

- Specifications : ASTM A182 / ASME SA182

- Standard : ASME B16.11 & BS 3799

- Size : 1/8” NB to 4” NB

- Class : 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

- Grades : Copper Nickel 90/10 (C70600), Cupro Nickel 70/30 (C71500)

SERVICES & CERTIFICATES

- Testing Facility Available : Mechanical Tests, Chemical Analysis, Ultrasonic test, PMI test, Corrosion test, Metallography Test, Hydrostatic test, Radiography test, Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 and 3.2 as well as NABL lab test reports