SPECTACLES/LONG WELD NECK FLANGES

Home / Forged Flanges / SPECTACLES/LONG WELD NECK FLANGES

Forged Flanges

Products

Get a Free Quote

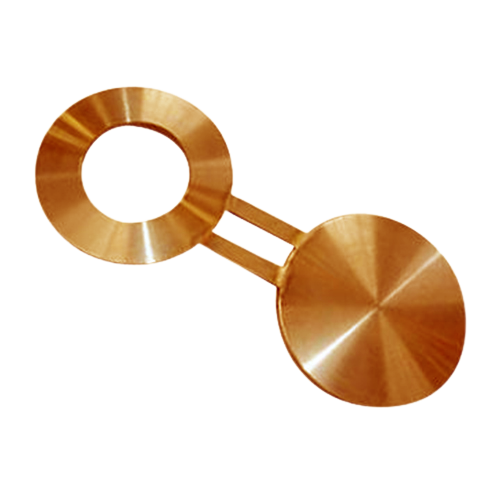

COPPER NICKEL SPECTACLES/LONG WELD NECK FLANGES

Nexus Alloys and Steels take pride in producing Copper Nickel Spectacles/Long Weld Neck Flanges, a perfect fusion of durability and adaptability. Crafted with precision from high-quality copper-nickel alloy, these flanges ensure a prolonged lifespan and robust performance. The spectacles/long weld neck design establishes a resilient, high-pressure connection, making these flanges the preferred choice across a wide range of industrial applications. Thanks to the copper-nickel alloy's outstanding corrosion resistance, these flanges thrive in challenging environments

DESCRIPTION

As a trusted name in the industry, Nexus Alloys and Steels guarantees that these flanges meet the highest standards of quality and performance. Each flange undergoes meticulous testing and inspection to ensure peak functionality. Copper Nickel Spectacles/Long Weld Neck Flanges by Nexus Alloys and Steels provide an indispensable solution for creating secure, high-pressure connections. These flanges facilitate robust, permanent connections through welding, making them a versatile choice for environments with high-pressure demands

Key Features of these flanges include

- High-Pressure Connections : Designed for strong, permanent connections through welding, ideal for high-pressure scenarios

- Versatile Sizing and Compliance : Copper Nickel Spectacles/Long Weld Neck Flanges are available in a diverse range of sizes, grades, and industry standards, offering customized solutions for precise fits and optimal performance

- Adaptability : Excelling in a wide range of applications, from high-pressure systems to alloy steel requirements, these flanges provide secure connections tailored to the specific needs of various industries

- Wide Industry Application : Deployed across sectors such as Aerospace and Defence, Nuclear Power, and Oil and Gas, these flanges are available in sizes ranging Upto 12". They adhere to the ANSI/ASME B 16.5 & 16.48 Standard with pressure classes including 150#, 300#, 600#, 900#, 1500#, and 2500# in ASA 150 and ASA 300

GRADES

- Cu-Ni 90/10 (UNS C70600) Spectacles/Long Weld Neck Flange : Comprising 90% copper and 10% nickel, this grade demonstrates exceptional corrosion resistance, finding applications in marine engineering, desalination, and heat exchanger systems

- Cu-Ni 70/30 (UNS C71500) Spectacles/Long Weld Neck Flange : With a composition of 70% copper and 30% nickel, Cu-Ni 70/30 excels in environments where corrosion resistance is crucial, widely used in marine and chemical processing industries, offering a balanced combination of strength, ductility, and biofouling resistance

TECHNICAL SPECIFICATION

- Flange Type : Spectacle Flange

- Manufacturing Standard : ANSI/ASME B 16.5

- Size Range : Upto 12”

- Flange Face Type : Flat Face (FF), Raised Face (RF)

- Long Weld Neck : BSPT, NPT

- Pressure Classes : 150#, 300#

- Conformance : ASA 150 and ASA 300 standards

- Available Pressure Classes : 150#, 300#, 600#, 900#, 1500#, 2500#

- Flange Type : Spectacle Flange

- Manufacturing Standard : ANSI/ASME B 16.5

- Size : Upto 12" - Class 150, Class 300, Class 600 & PN 10, PN 16, PN 25, PN 40

- Flange Face Type : Flat Face (FF), Raised Face (RF)

- Long Weld Neck : BSPT, NPT

- Conformance : ASA 150 and ASA 300 standards

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports