SLIPON FLANGES

Home / Forged Flanges / SLIPON FLANGE

Forged flanges

Products

Get a Free Quote

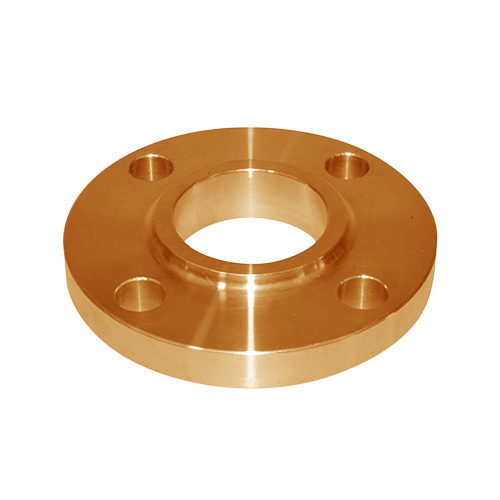

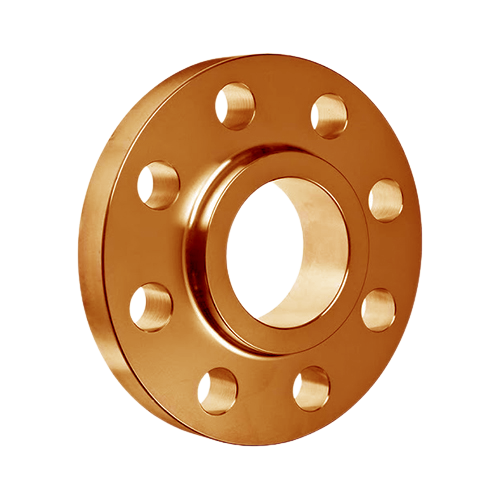

COPPER NICKEL SLIPON FLANGES

Nexus Alloys & Steel, a market leader, manufactures and distributes Copper Nickel Slip-On Flanges, which are essential for dismantling pipe joints. These flanges are kept together by inner and outer fillet welds. Depending on the design (FF), they have either Raised (RF) or Flat (FF) faces. The height of the Slip-On Raised Face Flange (SORF) is critical for the proper functioning of piping systems since it links pipes, valves, pumps, and other components. This product complies with a number of standards, including ANSI/ASME B16.5, DIN, AWWA, and API

DESCRIPTION

Slip-On Flanges, which are intended to easily slip over pipe ends and firmly weld in place, are an essential component in a wide range of pipeline applications across industries. Nexus Alloys, a well acknowledged pioneer in the manufacturing of Copper Nickel Slip-On Flanges, serves customers across industries. We consider our clients to be valued partners, offering not just goods but also a dedication to great service. Our Slip-On Flanges are made in a variety of forms, sizes, and dimensions to satisfy the precise needs of our discriminating customers

GRADES

- Cu-Ni 90/10 (UNS C70600) Slip-on Flanges : These flanges provide resistance to corrosion, making them ideal for connections between pipes. The dependable functioning of these flanges is ensured by their conformance to industry requirements

- Cu-Ni 70/30 (UNS C71500) Slip-on Flanges : These flanges provide resistance to corrosion and secure pipe connections, and they conform to industry standards to ensure the highest possible level of performance

TECHNICAL SPECIFICATION

- ASTM Standard : ASTM B111 ASME SB111 / ASTM B466 ASME SB466 / ASTM B 467 ASME SB467 / ASTM B543, B552 ASME SB543 SB552,ASTM B151

- Size : Upto 12" - Class 150, Class 300, Class 600 & PN 10, PN 16, PN 25, PN 40

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports