BLIND FLANGES

Home / Forged Flanges / BLIND FLANGES

Forged Flanges

Products

Get a Free Quote

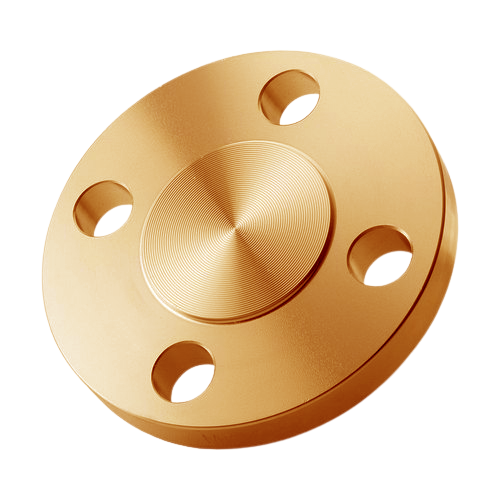

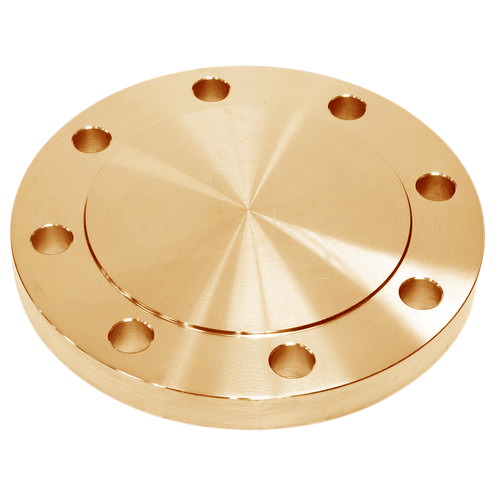

COPPER NICKEL BLIND FLANGES

Nexus Alloys & Steel is an industry leader in the Manufacturing and Exporting of Copper Nickel Blind Flanges, which are intended to seal the ends of pipes, valves, and pressure vessels specifically. The utilization of attachment holes and gasket sealing rings, which are included in these flanges, makes pipe connections more straightforward. Blind Flanges are compliant with ANSI/ASME B16.5, B16.47, B16.48, DIN, AWWA, and API standards. They find widespread use in a variety of sectors, including petrochemicals, shipbuilding, power plants, water treatment, and chemical manufacturing. The diameter may range anywhere from a few inches to sixty inches, and it is available in a variety of sizes

DESCRIPTION

Blind flanges are components that are necessary in piping systems and industrial applications. They play a significant part in the process of sealing or shutting the end of a pipeline or vessel. Solid disks that do not have a central hole are known as flanges. They are often used to either stop the flow of a pipeline or to seal the end of a pipeline, thus establishing a barrier that prevents leaking. Nexus Alloys & Steel, a major producer, is responsible for the production of Copper Nickel Blind Flanges, which, in comparison to other varieties, need somewhat less machining. The fact that they are often heavier than other alternatives since they do not include a bore makes them good choices. While the majority of the time, blanks are offered to complement slip-on and weld-neck flanges, there is also the possibility of modification to unique requirements

GRADES

- Cu-Ni 90/10 (UNS C70600) Blind Flanges : These flanges, made of copper-nickel alloy 90/10, offer excellent corrosion resistance and thermal stability. Ideal for marine and chemical applications, ensuring reliable sealing in diverse environments

- Cu-Ni 70/30 (UNS C71500) Blind Flanges : Crafted from copper-nickel alloy 70/30, these blind flanges provide superior corrosion resistance in harsh conditions. Well-suited for offshore and marine industries, ensuring dependable closure and durability

TECHNICAL SPECIFICATION

- ASTM Standard : ASTM B151

- Size : Upto 12" - Class 150, Class 300, Class 600 & PN 10, PN 16, PN 25, PN 40

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports