SOCKET WELD FLANGES

Home / Forged Flanges / SOCKET WELD FLANGES

Forged Flanges

Products

Get a Free Quote

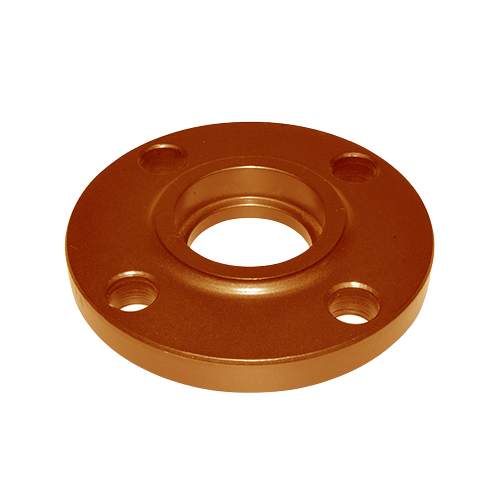

COPPER NICKEL SOCKET WELD FLANGES

Copper Nickel Socket Weld Flanges, brought to you by Nexus Alloys and Steels, embody a perfect fusion of robustness and adaptability. These flanges are meticulously engineered and constructed from top-tier copper-nickel alloy, promising durability and a long service life. The socket weld design ensures a strong, leak-proof connection, making these flanges a popular choice for a variety of industrial applications. The copper-nickel alloy imparts excellent corrosion resistance, rendering these flanges suitable for deployment in demanding conditions

DESCRIPTION

Nexus Alloys and Steels, a distinguished name in the industry, guarantees that these flanges conform to the most stringent standards of quality and performance. Each flange undergoes comprehensive testing and inspection to ensure peak functionality. Copper Nickel Socket Weld Flanges by Nexus Alloys and Steels are a vital solution for creating secure, leak-proof connections. These flanges enable robust, permanent connections through socket welding, making them a versatile choice for environments where high pressure and vibration are prevalent

Key Features of these flanges include

- Leak-Proof Connections : They facilitate strong, permanent connections through socket welding, ideal for high-pressure and high-vibration situations

- Broad Sizing and Compliance : Copper Nickel Socket Weld Flanges are available in a wide variety of sizes, grades, and industry standards, offering customized solutions to ensure a precise fit and optimal performance

- Versatility : These flanges are effective in a broad spectrum of applications, from high-pressure systems to alloy steel requirements, delivering secure connections tailored to the specific needs of diverse industries

- Extensive Industry Application : Used across sectors such as Aerospace and Defence, Nuclear Power, and Oil and Gas, these flanges are available in sizes ranging Upto 12". They comply with the ANSI/ASME B 16.5 Standard with pressure classes including 150#, 300#, 600#, 900#, 1500#, and 2500# in ASA 150 and ASA 300

GRADES

- Cu-Ni 90/10 (UNS C70600) Socket Weld Flange : This grade, composed of 90% copper and 10% nickel, exhibits exceptional corrosion resistance in various environments. Known for its versatility, Cu-Ni 90/10 is used in marine engineering, desalination, and heat exchanger systems

- Cu-Ni 70/30 (UNS C71500) Socket Weld Flange : With a composition of 70% copper and 30% nickel, Cu-Ni 70/30 thrives in environments where corrosion resistance is crucial. Extensively used in marine and chemical processing industries, this grade offers an optimal blend of strength, ductility, and resistance to biofouling

TECHNICAL SPECIFICATION

- Specifications : ASTM B151 UNS C70600, CuNi10Fe1.6Mn, 7060X,C71500

- Dimensions : ASME B16.5, 16.48

- Size : Upto 12" - Class 150, Class 300, Class 600 & PN 10, PN 16, PN 25, PN 40

- Threaded : BSPT, NPT

- Flange Face Type : Flat Face (FF), Raised Face (RF)

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports