Valves

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

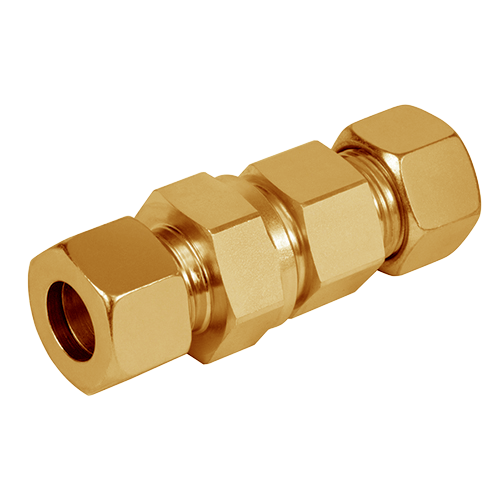

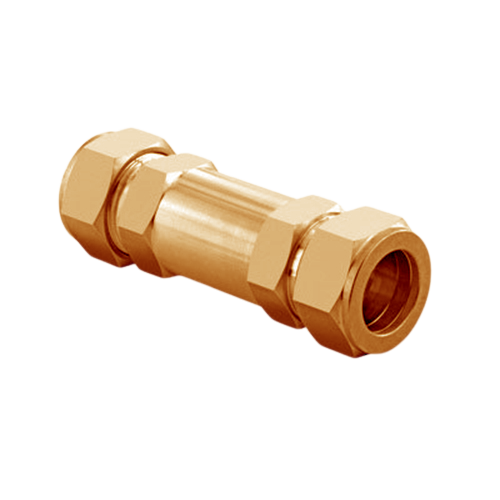

COPPER NICKEL CHECK VALVE

Nexus Alloys and Steel is a well-known producer and supplier of high-quality Copper Nickel Check Valves. We contribute substantial knowledge to this subject, which is widely employed in the oil and gas industry for accurate flow control in tough and dangerous settings. Our check valves are appropriate for all forms of liquid-based hydraulic systems and are rigorously tested to guarantee that our clients get a perfect range. These check valves may work in any spatial orientation thanks to a dependable tube assembly and a stainless steel seat type construction. In addition, we provide a wide range of high-quality check valves at reasonable costs

DESCRIPTION

A check valve, also known as a non-return valve or one-way valve, is a mechanical device that allows fluid (liquid or gas) to flow in only one direction. A check valve's principal purpose is to prevent backflow or backstreaming, ensuring that fluid moves in the proper direction and does not reverse course. Quality is non-negotiable at Nexus Alloys and Steel. Each check valve is rigorously tested to verify that it meets or exceeds industry requirements. Our dedication to quality assurance ensures that you obtain dependable items that will last even in the most demanding settings. Our effective distribution network guarantees that our high-quality check valves get at your door on time, no matter where you are

GRADES

- Cu-Ni 90/10 (UNS C70600) Check Valve : Long-lasting check valve made of Copper-Nickel alloy 90/10, which is recognized for its corrosion resistance and ensures dependable performance in a variety of industrial applications

- Cu-Ni 70/30 (UNS C71500) Check Valve : A high-quality check valve built of Copper-Nickel alloy 70/30 that offers good corrosion resistance and reliable performance in a variety of conditions

TECHNICAL SPECIFICATION

- ASTM Standard : ASTM B151

- Range : 1/2" to 4" (3" as per shahzma)

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports