LONG-STUBENDS

Home / Buttweld Fittings / LONG-STUBENDS

BUTTWELD FITTINGS

Get a Free Quote

Toll Free Call :

+91 93216 51417

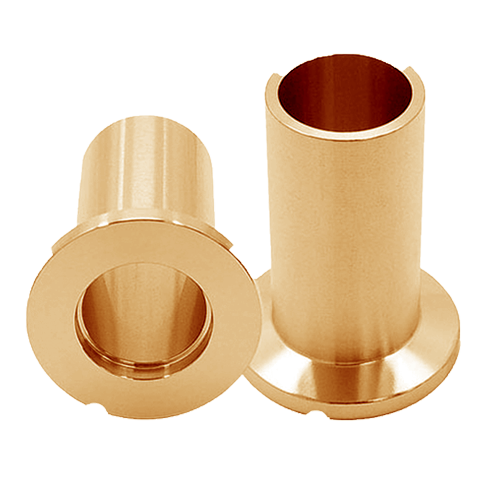

COPPER NICKEL LONG STUBENDS

Copper Nickel Long Stubends by Nexus Alloys and Steels are a type of pipe fitting that are designed to provide a connection between two lengths of pipe. These fittings are made from Copper Nickel in grades Cu-Ni 90/10 and Cu-Ni 70/30, known for their excellent resistance to corrosion and durability. These Long-Stubends are made with great care, which makes them a great choice for a wide range of industrial uses. They are available in different wall thicknesses, sizes, types, lengths, and can be either seamless or welded

DESCRIPTION

Nexus Alloys and Steels manufactures these Long-Stubends at their state-of-the-art production facility using a novel manufacturing process and cutting-edge technology. They ensure that all their products comply with all fittings regulations. With a highly qualified professional expert team and a dedicated workforce, Nexus Alloys and Steels guarantees that you will receive a high-quality Long-Stubend that is simple to put on and worth the money

Key Features of Copper Nickel Long-StubEnds

- Composition : The most common composition of the alloy is 82% copper and 18% nickel. However, there are also other types of CuNi alloys such as the 90/10 and 70/30 alloys

- Properties : High thermal stability, excellent electrical conductivity, good mechanical strength, compatibility with other materials, antibacterial properties, and long-term durability

- Formability and Toughness : Copper-Nickel alloy has adequate strength but good ductility. This makes it suitable for applications where formability and toughness are required

- Applications : CuNi alloys are used extensively in various industries and applications due to their unique combination of properties

GRADES

- Cu-Ni 90/10 (UNS C70600) : This grade is also known as Copper Nickel 90/10. It is composed of 90% copper and 10% nickel along with iron and manganese which provide high strength and corrosion resistance. This alloy is widely used in marine applications due to its excellent resistance to seawater, brine water, organic compounds, salts, diluted non-oxidizing acids, and more

- Cu-Ni 70/30 (UNS C71500) : Also known as Copper Nickel 70/30, this grade contains 70% copper and 30% nickel along with small amounts of iron and manganese to enhance overall strength and corrosion resistance. It offers even better resistance to corrosion and erosion compared to Copper Nickel 90/10 and is used in severe duty conditions in marine and industrial services

TECHNICAL SPECIFICATION

- Standard : ASME B16.9, MSS-SP-43

- Material : Copper Nickel Alloy

- Types : Fitting for butt welding into copper-nickel-alloy pipelines

- Nickel Alloy Long-Stubend : ASTM / ASME SB 336 UNS 2200 (Nickel 200), UNS 2201 (Nickel 201), UNS 4400 (Monel 400), UNS 8020 (Alloy 20 / 20 CB 3), UNS 8825 Inconel (825), UNS 6600 (Inconel 600), UNS 6601 (Inconel 601), UNS 6625 (Inconel 625), UNS 10276 (Hastelloy C 276)

- Copper Nickel Carbon Steel Long-Stubend : Copper Nickel 90/10 (C70600 ) Long-Stubend, Cupro Nickel 70/30 (C71500) Long-Stubend, UNS C71640 Mss Sp 95 Long-Stubend

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports