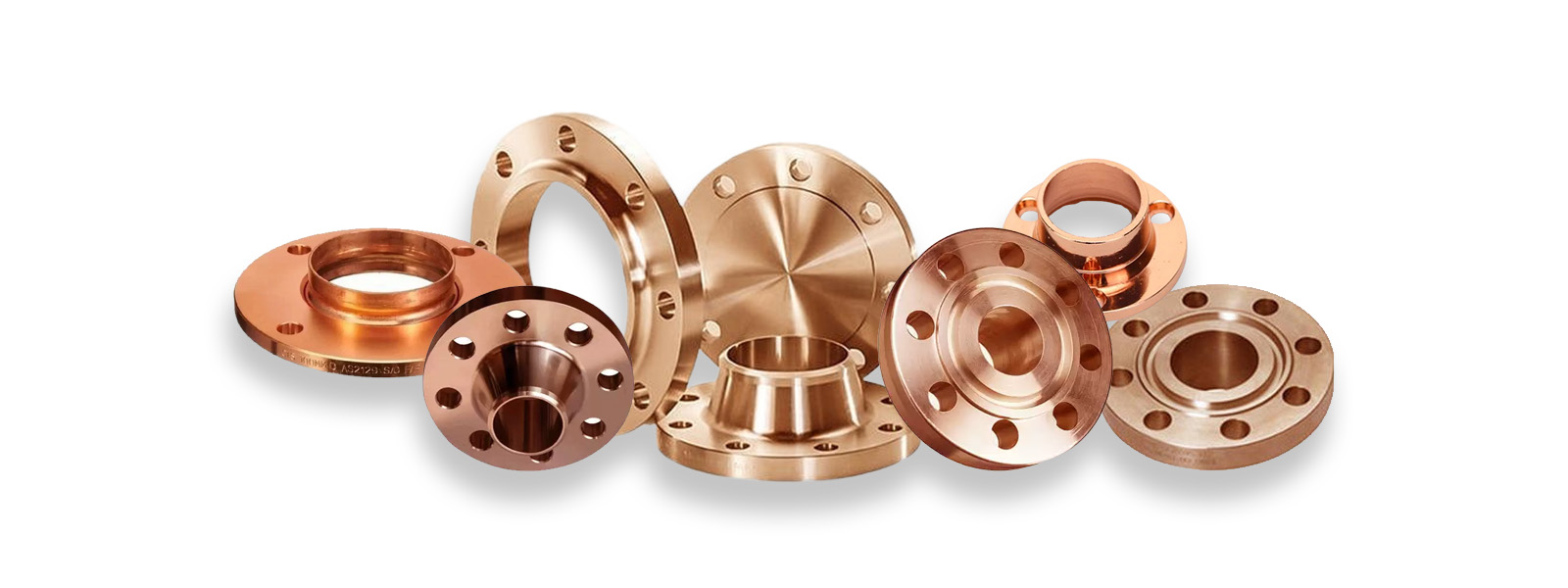

This is especially the case in industries where reliability and durability are of essence, the type of material used in manufacturing of flanges and other critical parts can define the overall performance of the equipment. When it comes to the vast array of choices, copper nickel flanges are unrivaled in terms of strength and resistance to corrosion as well as flexibility. This blog post goes deeper into the details of copper nickel forged flanges and why they are the go-to solution in numerous applications

The Unique Composition of Copper Nickel

Copper nickel also known as Cupro Nickel is an alloy that is made from copper and nickel and has small proportions of iron and manganese. The particular characteristics of these materials make copper nickel alloys what they are: highly resistant to seawater corrosion, high tensile strength, and high durability

The most popular grade in copper nickel flanges is the 90/10 copper nickel alloy that is made of 90% copper and 10% nickel. This composition gives the best combination of strength and corrosion resistance which is important in marine and offshore applications where there is always exposure to salt water

Why Forged Flanges?

In the case of flanges, the type of manufacturing that is used has a significant impact on the flanges’ performance. Forging is a metal working process that uses pressure to shape the material and this is usually done at a high temperature. This method causes the grain structure of the metal to be aligned and therefore increases the forged strength. This is especially so in applications where the flanges are likely to be exposed to high pressures, high temperatures or corrosive conditions

Forged copper nickel pipe flanges have better mechanical characteristics than the cast copper nickel pipe flanges. The forging process improves the strength and the fatigue limits of the flanges so that they can be used under extreme conditions of operation without degrading their performance. Furthermore, the enhancement of the grain structure through forging reduces the chances of the formation of porosity and other detrimental features that may compromise the strength of the flange

Applications of Copper Nickel Forged Flanges

The unique properties of copper nickel forged flanges make them suitable for a wide range of applications, particularly in industries where corrosion resistance and durability are critical. Some of the most common applications include

- Marine Industry : Copper nickel is highly resistant to seawater corrosion, and therefore, it is widely used in the ship building industry especially for flanges, which are used in piping systems that require a tight seal in marine environment.

- Oil and Gas Industry : Copper nickel forged flanges are used in offshore oil and gas platforms because they are capable of withstanding the harshest conditions such as exposure to seawater, chemicals and high temperatures.

- Desalination Plants : Copper nickel alloys are resistant to biofouling and corrosion in saline environments, and therefore, they are widely used in desalination plants where they are used in piping systems that transport seawater and desalinated water.

- Power Generation : Copper nickel flanges are important parts in power plants especially in power plants that use seawater in their cooling systems

Benefits of Copper Nickel Forged Flanges

The decision to use copper nickel forged flanges is often driven by a combination of factors that contribute to their overall cost-effectiveness and performance

- Corrosion Resistance : The corrosion resistance of copper nickel particularly in seawater and other harsh environments makes it to stand out in terms of durability and low maintenance.

- Mechanical Strength : This enhances the mechanical characteristics of the flanges such as tensile strength, fatigue strength, and toughness in order to withstand pressure and temperature.

- Thermal Stability : Copper nickel alloys also do not deform or corrode at high temperatures, which is important in use in power generation and chemical industries.

- Ease of Fabrication : However, copper nickel alloys are relatively easy to machine and weld and thus the production of various flange designs that can meet certain specifications is easily possible

Choosing the Right Supplier

Given the critical role that copper nickel flanges play in various industries, it’s essential to source them from a reliable Cupro Nickel Flanges Exporter and Stockist. A reputable supplier will not only provide high-quality flanges but also ensure that they meet the necessary industry standards and specifications

When choosing a supplier, consider factors such as their experience, range of products, and ability to provide technical support. A well-established exporter and stockist will have a proven track record of delivering flanges that perform reliably in the most demanding conditions

Conclusion

In summary, copper nickel forged flanges offer a unique combination of strength, corrosion resistance, and versatility that makes them an ideal choice for a wide range of applications. Whether used in the marine industry, oil and gas sector, or power generation, these flanges deliver reliable performance under even the harshest conditions. By choosing the right Cupro Nickel Flanges Exporter and Stockist, you can ensure that your piping systems are equipped with components that meet the highest standards of quality and durability

You can Contact Nexus Cupro Nickel at sales@nexuspipefittings.com to learn more about the Copper Nickel Forged Flange and their use in industries.