In industries where exposure to seawater, acidic solutions, and other aggressive environments is common, selecting the right material for durability and performance is crucial. Copper nickel round bars are widely used in such conditions due to their excellent corrosion resistance, mechanical strength, and thermal stability. This article explores the essential considerations for selecting the right copper nickel round bar in corrosive media environments.

Understanding Copper Nickel Alloys

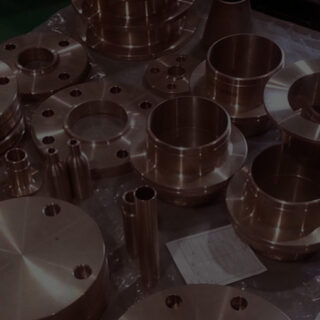

Copper nickel (Cu-Ni) alloys are widely recognized for their superior resistance to corrosion, particularly in marine and chemical processing applications. The two most common grades used in industrial applications are :

- Copper Nickel 90 10 Round Bar (Cu-Ni 90/10) : Contains 90% copper and 10% nickel, offering excellent corrosion resistance and good strength.

- Copper Nickel 70 30 Round Bar (Cu-Ni 70/30) : Contains 70% copper and 30% nickel, providing enhanced mechanical strength and superior resistance to biofouling and erosion.

Both alloys are widely used in seawater systems, desalination plants, offshore structures, and shipbuilding due to their outstanding resistance to saltwater corrosion.

Factors to Consider for Selection in Corrosive Environments

1. Corrosion Resistance

The primary reason for choosing copper nickel round bars is their remarkable resistance to corrosion in seawater, brine solutions, and acidic environments. The natural formation of a protective oxide layer on their surface prevents rapid degradation, making them ideal for harsh conditions.

- Cu-Ni 90/10 : Best suited for moderate corrosive conditions where exposure to seawater and mildly acidic solutions is common.

- Cu-Ni 70/30 : Preferred for high-intensity applications, including offshore platforms and heat exchangers, where stronger corrosion resistance is required.

2. Mechanical Strength & Durability

Both copper nickel 90 10 round bar and copper nickel 70 30 round bar exhibit excellent mechanical strength, which enhances their durability in marine and industrial environments. However, Cu-Ni 70/30 is preferred where higher tensile strength and toughness are needed, while Cu-Ni 90/10 is more cost-effective and sufficient for many applications.

3. Thermal and Electrical Conductivity

Copper nickel alloys exhibit good thermal and electrical conductivity, making them suitable for applications where heat transfer is essential. For example :

- Heat exchangers

- Condensers

- Piping systems in power plants.

Applications of Copper Nickel Round Bars in Corrosive Media

- Marine & Offshore Industry : In marine environments, exposure to seawater leads to rapid material degradation if inappropriate metals are used. Copper nickel 90 10 round bars are commonly used in boat hulls, propeller shafts, and heat exchangers, whereas copper nickel 70 30 round bars are used in offshore oil rigs and seawater piping systems due to their superior resistance.

- Chemical Processing Plants : Industries that handle acidic solutions and chemical compounds require materials that can withstand highly corrosive media. Copper nickel alloys are extensively used in chemical processing equipment, storage tanks, and pipelines where resistance to sulfuric and hydrochloric acids is needed.

- Power Generation : In power plants, copper nickel bars are used in heat exchangers and cooling systems due to their ability to withstand extreme temperatures and resist scaling. Cu-Ni 70/30 is preferred in nuclear and thermal power stations where durability under high-pressure conditions is essential.

Comparing Copper Nickel 90/10 and 70/30 for Corrosive Environments

| Property | Copper Nickel 90/10 | Copper Nickel 70/30 |

|---|---|---|

| Corrosion Resistance | High | Very High |

| Mechanical Strength | Moderate | High |

| Thermal Conductivity | Excellent | Good |

| Biofouling Resistance | Moderate | Excellent |

| Cost | Lower | Higher |

Why Choose Nexus Cupro Nickel?

Nexus Cupro Nickel, a leading manufacturer and exporter of copper nickel round bars in Mumbai, India, provides high-quality copper nickel 90 10 round bar and copper nickel 70 30 round bar. Our products are engineered to perform in the most demanding corrosive environments, ensuring long service life and superior performance.

Conclusion

Selecting the right copper nickel round bar for a corrosive media environment depends on factors such as corrosion resistance, mechanical strength, and application requirements. While copper nickel 90 10 round bars offer excellent corrosion resistance at an economical price, copper nickel 70 30 round bars provide superior strength and durability for extreme conditions. Nexus Cupro Nickel ensures the highest quality standards to meet the needs of industries worldwide.

For inquiries or to explore our range of copper nickel round bars, Contact Nexus Cupro Nickel today!