OD-PLUG

Home / Tube Fittings / OD-PLUG

TUBE FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

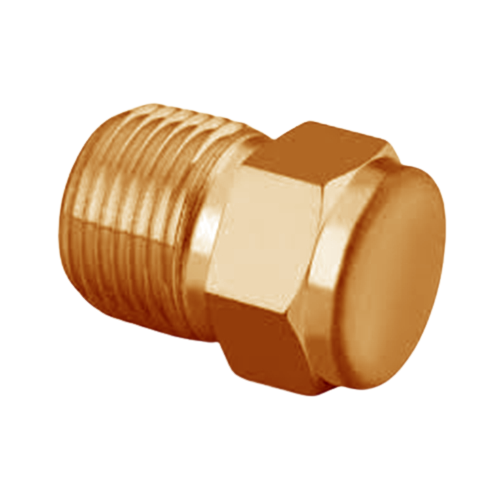

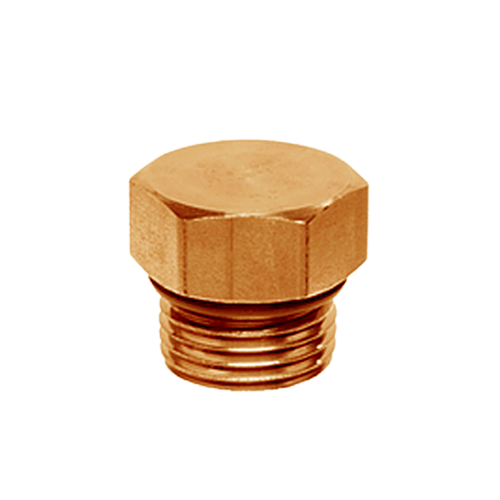

COPPER-NICKEL OD-PLUG

The Copper-Nickel OD-Plug by Nexus Alloys and Steels, often used in marine applications, is a type of fitting designed to be inserted into the open end of a pipe or tube. The term “OD” stands for “Outside Diameter”, indicating that the plug’s size corresponds to the outer diameter of the pipe or tube it is meant to fit. Copper-Nickel, also known as Cupronickel, is a valuable material in this context due to its excellent resistance to corrosion, especially salt water corrosion. This makes Copper-Nickel OD Plugs particularly useful in marine environments where they are exposed to seawater

DESCRIPTION

These plugs by Nexus Alloys and Steels are typically used to cap off the ends of pipes or tubes, preventing fluid flow and protecting the system from contaminants. They are an essential component in a variety of systems, including plumbing, heating, and cooling systems. They can also be used in the oil and gas industry, shipbuilding, desalination plants, and other industrial applications

Key Features of Copper Nickel OD-Plug

- Material : Made from Copper-Nickel alloy, also known as Cupronickel, which is known for its excellent resistance to corrosion, especially salt water corrosion

- Marine Applications : Due to its corrosion resistance, it is particularly useful in marine environments where they are exposed to seawater

- OD Fitting : The term “OD” stands for “Outside Diameter”, indicating that the plug’s size corresponds to the outer diameter of the pipe or tube it is meant to fit

- Function : These plugs are typically used to cap off the ends of pipes or tubes, preventing fluid flow and protecting the system from contaminants

- Versatility : They are an essential component in a variety of systems, including plumbing, heating, and cooling systems. They can also be used in the oil and gas industry, shipbuilding, desalination plants, and other industrial applications

- Selection : When selecting a Copper-Nickel OD Plug, it’s important to consider the specifications of the pipe or tube it will be used with, including its outside diameter, wall thickness, and the type of fluid it will be exposed to. This ensures a secure fit and optimal performance

GRADES

- Cu-Ni 90/10 (UNS C70600) : This grade is known for its excellent resistance to corrosion, especially in marine environments. It is often used in applications where exposure to seawater is a concern. This alloy is composed of 90% copper and 10% nickel, blended with iron and manganese to deliver impressive strength

- Cu-Ni 70/30 (UNS C71500) : This grade has a slightly higher nickel content, which provides increased strength and corrosion resistance. This grade features 70% copper and 30% nickel, with minor additions of iron and manganese

TECHNICAL SPECIFICATION

- Material : Copper-Nickel

- Components : The plug consists of three precision-engineered components – Plug, Nut, and Circlip

- Applications : These plugs are ideal for high-pressure gasses, liquids, and vacuum applications

- Installation : They eliminate the need for welding and enable easy installation with wrenches or spanners

- ASTM Standard : ASTM B111 ASME SB111 / ASTM B466 ASME SB466 / ASTM B 467 ASME SB 467 / ASTM B543, B552 ASME SB543 SB552, ASTM B151

- Range : 1/2" to 2" - pressure rating class 5 KG bar to 50 KG bar (high pressure as per customer requirements).

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports