HOSE

Home / Tube Fittings / HOSE

TUBE FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

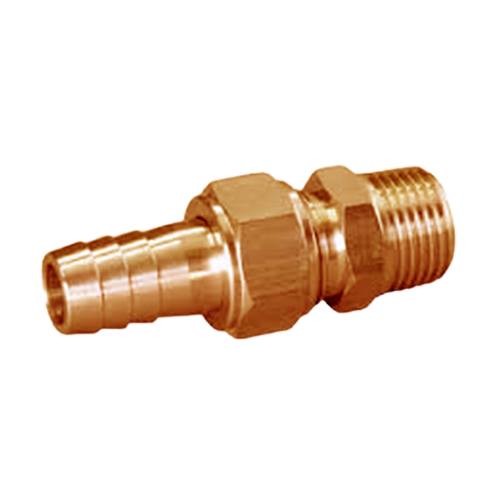

COPPER NICKEL HOSE

The Copper-Nickel Hose by Nexus Alloys and Steels is a type of flexible conduit often used in various industrial applications. It is made from a blend of copper and nickel, which gives it excellent corrosion resistance, strength, and durability. Copper-Nickel Hoses are particularly well-suited for use in harsh environments such as marine and offshore applications, where they can withstand exposure to saltwater and other corrosive elements. They are also resistant to biofouling, making them ideal for use in systems where cleanliness and hygiene are paramount

DESCRIPTION

In addition to their robust physical properties, Copper-Nickel Hoses by Nexus Alloys and Steels also offer excellent thermal conductivity, making them suitable for use in heat exchange systems. Their flexibility allows for easy installation and accommodation of movement in dynamic systems. Overall, a Copper-Nickel Hose is a reliable and versatile component that can meet the demands of various challenging industrial applications

Key features of Copper Nickel Hoses

- Material : Made from a blend of copper and nickel, providing excellent corrosion resistance and durability

- Environment Resistance : Ideal for harsh environments such as marine and offshore applications due to its resistance to saltwater and other corrosive elements

- Biofouling Resistance : Resistant to biofouling, making it suitable for systems where cleanliness and hygiene are important

- Thermal Conductivity : Offers excellent thermal conductivity, making it suitable for use in heat exchange systems

- Flexibility : Its flexibility allows for easy installation and accommodation of movement in dynamic systems

- Versatility : Can meet the demands of various challenging industrial applications due to its robust physical properties

GRADES

- Copper Nickel C71500 (70/30) : This alloy primarily consists of 70% copper and 30% nickel, with a small amount of iron. It has excellent tensile and yield strength, with tensile strength ranging between 515 and 690 MPa, and yield strength between 195 and 415 MPa. It exhibits excellent resistance to stress corrosion cracking and pitting corrosion. This alloy is widely used in applications that demand high strength and corrosion resistance

- Copper Nickel C70600 (90/10) : This alloy contains 90% copper and 10% nickel, with small amounts of iron and manganese. It has excellent mechanical properties, providing high strength and toughness even at elevated temperatures. The alloy has excellent corrosion resistance, thermal stability, and strength

- 6Mn CuNi 90/10 : This is another variant of the 90/10 copper-nickel alloy. It combines excellent resistance to uniform corrosion, remarkable resistance to localized corrosion in chlorinated seawater, and higher erosion resistance than other copper alloys and steel. Furthermore, it is resistant to biofouling, providing various economic benefits

- CuNi 70/30 : This is another variant of the 70/30 copper-nickel alloy. It is resistant to stress corrosion cracking and has high strength. This alloy is resistant to impingement corrosion and prevents attack by alkali and acidic media. It is used in shipbuilding, desalination plants, evaporator vessels, and heat exchanger systems

TECHNICAL SPECIFICATION

- Composition : The common compositions for 90-10 and 70-30 Cu-Ni alloys are as follows

- 90-10 Cu-Ni (UNS C70600) : Cu (Remainder), Pb (0.05*), Fe (1.0-1.8), Zn (1.0*), Ni (including Co) (9.0-11.0), Mn (1.0)

- 70-30 Cu-Ni (UNS C71500) : Cu (Remainder), Pb (0.05*), Fe (0.4-1.0), Zn (1.0*), Ni (including Co) (29.0-33.0), Mn (1.0)

- Standards : There are several international and national standards for ordering wrought and cast forms of copper-nickel alloys. For example, the American (ASTM), European (EN), and International Standards (ISO) have specific numbers for different product forms like plate, sheet, strip, tube, rod, wire, forgings, and castings

- Design : There are specific design standards for copper-nickel piping systems in marine applications. For example, the DIN specifications cover 90-10 Cu-Ni piping for offshore applications

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports