BULKHEAD UNION

Home / Tube Fittings / BULKHEAD UNION

TUBE FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

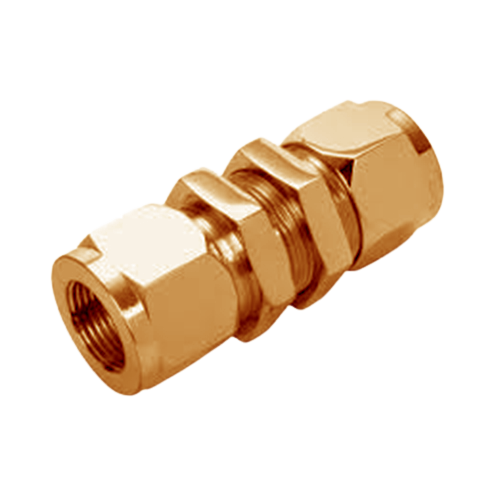

COPPER NICKEL BULKHEAD UNION

The copper-nickel Bulkhead Union by Nexus Alloys and Steels is a type of tube fitting used in various industries, including oil and gas, petrochemical, and water treatment. These unions are crafted from high-quality copper-nickel alloys, such as C71500, which consists of 70% copper and 30% nickel. Bulkhead Unions by Nexus Alloys and Steels are designed to provide leak-free joints and are known for their high tensile strength, unique forming abilities, and good reusability. They are highly resistant to stress corrosion, especially in saltwater environments. This makes them particularly suitable for applications that involve exposure to seawater or other corrosive conditions

DESCRIPTION

These fittings are available in various types and sizes, and can be custom-designed to meet specific requirements. They undergo rigorous strength testing to ensure compliance with international standards. Copper-nickel bulkhead unions are a testament to the versatility and durability of copper-nickel alloys, offering superior quality and performance in demanding industrial applications

Key Features of Copper-Nickel Bulkhead Union

- Material : Made from high-quality copper-nickel alloys like C71500, which is known for its excellent corrosion resistance and mechanical properties

- Corrosion Resistance : Exceptional resistance to corrosion, especially in saltwater and other harsh environments. This makes them ideal for marine applications

- High Strength : These unions have high tensile strength, ensuring durability and longevity

- Versatility : Available in various types and sizes, they can be used in a wide range of applications

- Leak-Proof : Designed to provide leak-free connections, enhancing the efficiency of the systems they are used in

- Reusability : They have unique forming abilities and good reusability, making them cost-effective in the long run

- Compliance with Standards : They undergo rigorous testing to ensure compliance with international standards

- Customizability : Can be custom-designed to meet specific requirements

GRADES

- Cu-Ni 90/10 (UNS C70600) : C70600, also recognized as Copper Nickel 90/10, is an alloy containing 90% copper and 10% nickel. It is reinforced with iron and manganese to offer robust strength and corrosion resistance. Widely utilized in marine applications, this alloy exhibits outstanding resilience against environmental factors such as seawater, brine water, organic compounds, salts, diluted non-oxidizing acids, and more

- Cu-Ni 70/30 (UNS C71500) : C71500, known as Copper Nickel 70/30, is composed of 70% copper and 30% nickel, with additional minor amounts of iron and manganese to improve overall strength and corrosion resistance. Demonstrating superior resistance to corrosion and erosion when compared to Copper Nickel 90/10, it finds application in demanding conditions in both marine and industrial services

TECHNICAL SPECIFICATION

- Material : Copper-Nickel

- Chemical Composition : Copper 88.6%, Nickel 10.0%, Iron 1.4%

- Mechanical Properties : Tensile strength is 45,000 psi, Yield strength is 18,000 psi, and Elongation is 35%

- Size : Available in sizes from 10 mm to 100 mm & 1/2” to 4”

- Standards : Conforms to MIL-T-16420K, Type I, Grade 1, ASTM B 466

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports