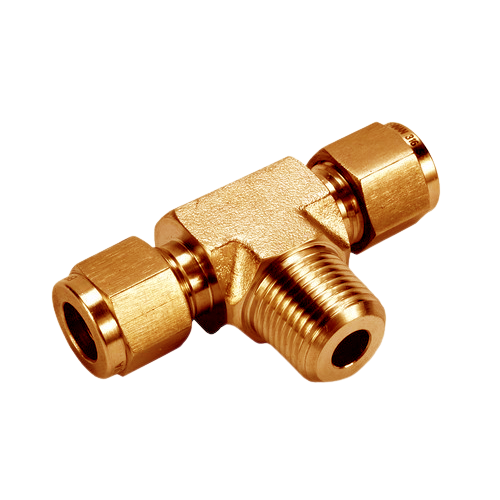

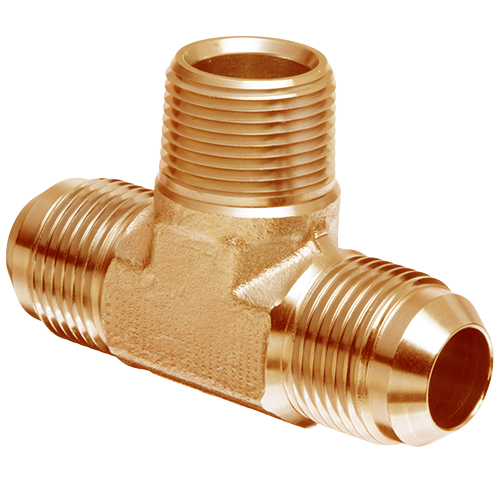

BRANCH TEE

Home / Tube Fittings / BRANCH TEE

tube fittings

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

COPPER NICKEL BRANCH TEE

Nexus Alloys and Steel is widely recognized as a reputable manufacturer of Copper Nickel Branch Tee Tube Fittings, serving customers worldwide with an outstanding reputation for excellence. Our Copper Nickel Branch Tee Tube Fittings are known for their precise engineering, incorporating state-of-the-art technologies and top-notch materials. These Ferrule Fittings are specifically designed to connect three pipes or tubes at right angles, playing a vital role in various applications and ensuring the smooth operation of fluid systems. The unique design features an outer thread on one supply line and inner threads on the other two, allowing for quick, secure, and reliable connections, especially when used with male branch tees

DESCRIPTION

A branch tee tube fitting serves as a connector that brings together three pipes or tubes at a single point, forming a T-shaped configuration. These fittings find extensive use across industries such as plumbing, HVAC, process piping, and other fluid handling systems. Our Copper Nickel Branch Tee Tube Fittings are meticulously engineered to provide seamless and efficient connections in piping systems, guaranteeing uninterrupted flow with minimal pressure drops. Crafted from high-quality copper nickel alloy, these fittings are well-suited for applications in marine environments, chemical processing plants, oil and gas industries

GRADES

- Cu-Ni 90/10 (UNS C70600) Branch Tee Tube Fittings : These fittings are expertly crafted from a Copper-Nickel alloy, specifically designed to provide exceptional corrosion resistance and long-lasting durability. With their seamless connections, they are suitable for a wide range of applications

- Cu-Ni 70/30 (UNS C71500) Branch Tee Tube Fittings : These fittings not only ensure strong connections for three right-angled pipes but also exhibit superior strength and resistance against corrosion. They are meticulously engineered to meet the diverse requirements of fluid systems with precision

TECHNICAL SPECIFICATION

- ASTM Standard : ASTM B111 ASME SB111 / ASTM B466 ASME SB466 / ASTM B 467 ASME SB467 / ASTM B543, B552 ASME SB543 SB552,ASTM B151

- Range : 1/2" to 2" - pressure rating class 5 KG bar to 50 KG bar (high pressure as per customer requirements)

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports