In the case of industrial applications especially in heat exchange systems, the material selection is very vital in the determination of the efficiency and durability of the equipment. One such critical part is the copper buttweld pipe fittings used in condensers. These fittings are crucial in achieving the best performance, dependability and efficiency as well as affordability. In this blog, we will discuss the importance of copper buttweld pipe fittings in condensers, especially the Cupro Nickel copper alloys and their influence on heat transfer rate and system performance

The Importance of Condensers

Condensers are essential in numerous applications in industries such as power, HVAC, and refrigeration industries. Their main purpose is to liquefy gaseous materials by cooling them down. This process depends on the ability to transfer heat from the gas to the cooling medium which in most cases is either water or air. Condensers’ performance greatly affects the efficiency and power usage of the whole system; therefore, the selection of condenser materials is crucial

Why Copper?

Copper was the material of choice for heat exchangers for many centuries because of its superior thermal conductivity, corrosion resistance, and ease of forming. These properties make it suitable for use in condenser tubes and fittings. However, for the industrial applications that require higher performance, there are copper alloys like Cupro Nickel that provide better advantages

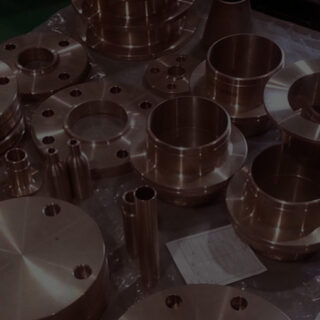

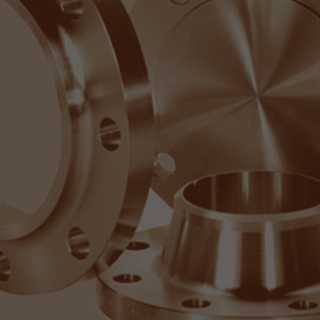

Copper Buttweld Pipe Fittings: The Backbone of Efficient Condensers

Copper buttweld pipe fittings are very crucial in joining different parts of the piping system in condensers. They provide a secure and leak-proof connection, which is necessary for the system’s integrity. Buttweld fittings are chosen over other types because they are suitable for high pressure services and the jointing process is butt-welded which minimizes the chances of leakage and corrosion

Cupro Nickel, an alloy of copper and nickel, is highly resistant to the corrosive attack of sea water and marine organisms. This makes it particularly useful in marine and coastal conditions where condensers are likely to encounter very unfavorable conditions. Apart from increasing the corrosion resistance of the alloy, nickel inclusion also increases the strength and durability of the alloy

- Enhanced Heat Transfer Efficiency : Heat transfer is one of the most notable attributes of the copper buttweld pipe fittings manufactured from Cupro Nickel. Copper itself is a good heat conductor, and nickel improves this characteristic of the alloy. This means that condensers that have Cupro Nickel fittings will work optimally and this will result in saving of energy as well as the cost of doing the operation.

- Durability and Longevity : Condensers are exposed to unfavorable working conditions such as high temperatures and corrosive atmosphere. Cupro Nickel fittings are very long lasting and thus, they do not require frequent replacements hence cutting on costs of maintenance and time. This makes it possible for the system to be able to stand the test of time without corroding hence providing the required performance.

- Versatility in Application : Cupro Nickel is a material that can be used in many fields due to its flexibility. Condensers that are used in power plants, desalination plants and marine vessels operate efficiently with Cupro Nickel buttweld fittings. Due to their high tolerance to environmental conditions without any compromise to their performance, they are widely used in various sectors

Installation and Maintenance: A Seamless Experience

The installation of copper buttweld pipe fittings is relatively straightforward, provided that proper procedures are followed. The seamless nature of buttweld fittings ensures a robust connection, eliminating the common issues associated with threaded or flanged fittings. Additionally, the maintenance of these fittings is minimal due to their high resistance to corrosion and biofouling. Regular inspections and cleaning are usually sufficient to keep the system in top condition

Economic and Environmental Benefits

Investing in high-quality copper buttweld pipe fittings for condensers not only makes economic sense but also has environmental benefits. The improved heat transfer efficiency translates to lower energy consumption, which reduces the carbon footprint of the operation. Moreover, the durability and longevity of Cupro Nickel fittings mean fewer replacements and less waste, contributing to more sustainable industrial practices

Conclusion

In the complex and demanding world of industrial heat exchange, the value of copper buttweld pipe fittings cannot be overstated. Their role in ensuring efficient and reliable operation of condensers is crucial. When enhanced with copper alloys like Cupro Nickel, these fittings offer unparalleled benefits in terms of heat transfer efficiency, durability, and versatility. By choosing the right materials for their condensers, industries can achieve significant cost savings, operational efficiency, and environmental sustainability. The integration of Cupro Nickel buttweld fittings is indeed a smart choice for any operation aiming for excellence in performance and longevity

You can Contact Nexus Cupro Nickel at sales@nexuspipefittings.com to know more about the Copper Buttweld Pipe Fittings and their role in condensers.