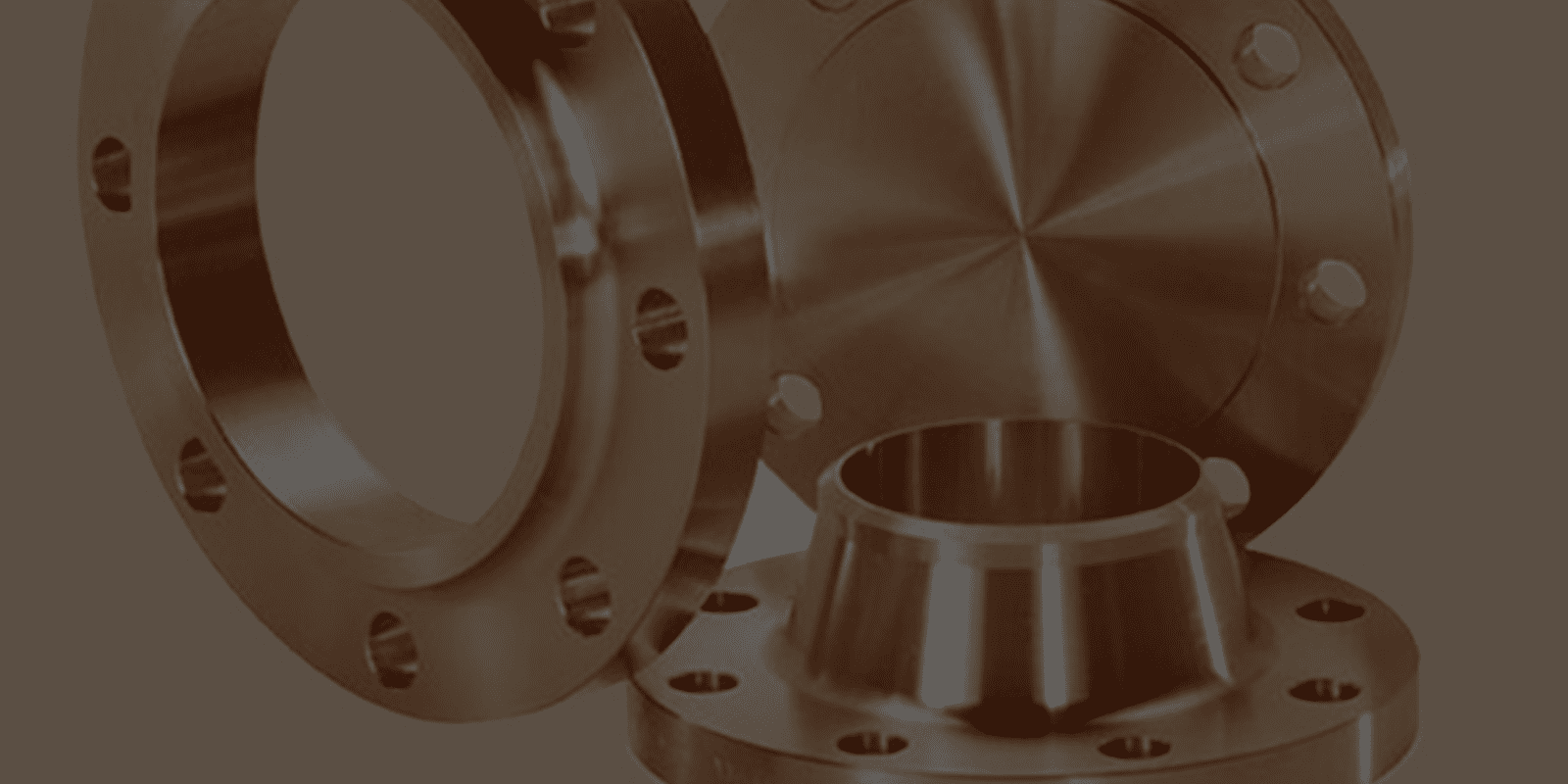

At Nexus Cupro Nickel, we specialize in the production of high-quality copper-nickel forged flanges, essential components widely used in marine, chemical processing, and oil & gas industries. The manufacturing process involves several critical steps, ensuring that every flange meets the stringent requirements of durability and performance. This article explores our comprehensive approach to the copper-nickel forging process, the intricacies of flange manufacturing process, the specialized copper-nickel metallurgy, and our rigorous flange quality control measures

Understanding the Copper-Nickel Metallurgy

The value of copper-nickel alloys is that they are resistant to corrosion, very durable, and antifouling. These properties make it suitable for harsh environments, where seawater resistance is particularly important. The key to copper-nickel metallurgy is controlling the composition of an alloy that has the ductility of copper and strong corrosion resistance characteristic because of nickel. At Nexus Cupro Nickel, our experts make sure that the alloy composition is tailored for superior performance to various equipment it may or will be employed in

The Copper-Nickel Forging Process

The process of forging begins during the selection of raw materials. This is the alloy, made by carefully melting high-quality copper and nickel. After preparation, the alloy will be subjected to a process known as forging. Copper-nickel needs to be heated and formed in a forge, which is the process of taking something past its melting point for shaping. The heated alloy is pressed or hammered into the desired shape, i.e., flanges. This type of forging provides superior mechanical properties such as toughness and fatigue strength which are important for the flanges required to resist high levels of pressure in corrosive environments

The Flange Manufacturing Process

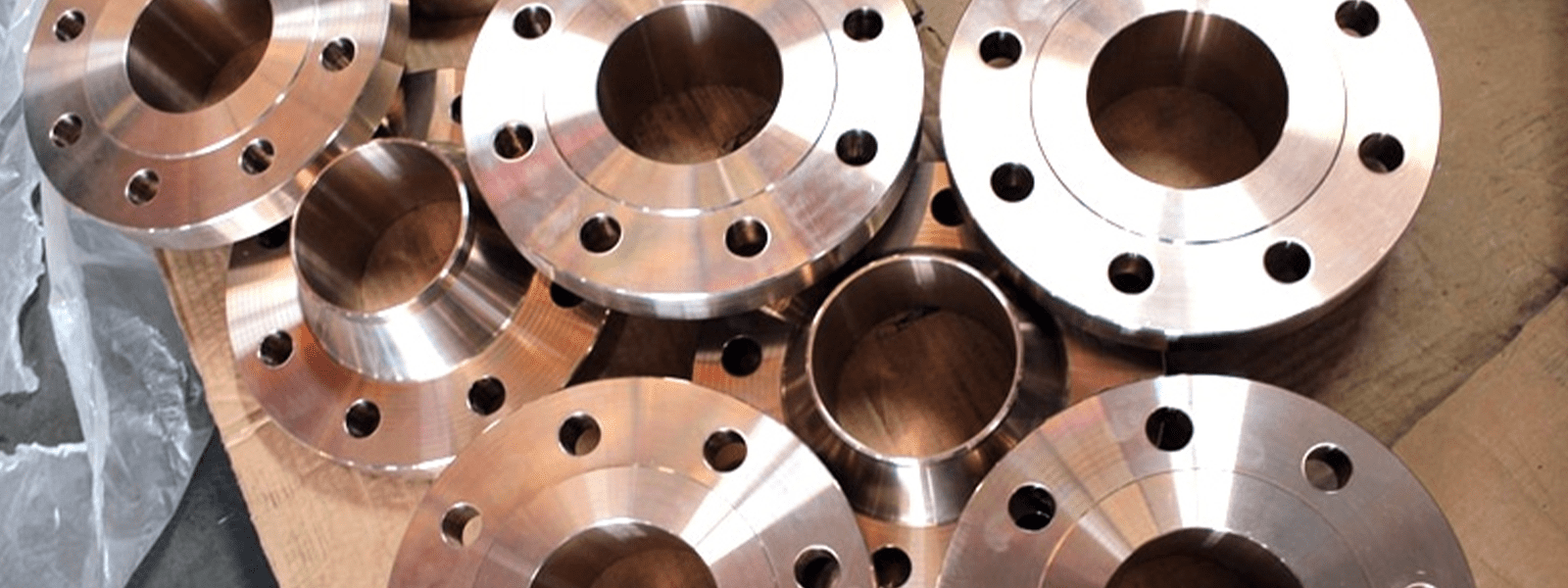

After forging, the rough flanges undergo several machining steps to achieve the precise dimensions required for specific applications. This includes cutting, turning, milling, and drilling, which ensure that each flange fits perfectly with the mating pipe. Precision in the flange manufacturing process is vital to prevent leaks and ensure the integrity of the entire piping system. At Nexus Cupro Nickel, we use state-of-the-art machinery and technology to maintain high accuracy and consistency across all our products

Flange Quality Control

Quality control is paramount in every stage of our manufacturing process. Each batch of copper-nickel flanges is subjected to rigorous testing and inspection to ensure they meet all industry standards and specifications. Our quality control measures include dimensional checks, material composition analysis, mechanical property testing, and non-destructive testing methods like ultrasonic and radiographic tests. These comprehensive quality checks guarantee that our flanges are reliable and perform exceptionally in their applications

Customization and Design Flexibility

Nexus Cupro Nickel recognizes the fact that every industry is different and so are their specific requirements, making customization imperative. Copper-nickel forged flanges come in customizable sizes, thicknesses, and bespoke design specifications to suit a wide range of pressures from different environments. This design versatility is what makes our offerings easily adaptable to work both independently and collaboratively with new installations or existing systems

Environmental Impact & Sustainability

Furthermore, at Nexus Cupro Nickel we also adhere to environmental stewardship. We are always working to reduce our waste and carbon footprint by streamlining our manufacturing processes. Copper-nickel alloys will also sustain over a longer period and this improved life cycle span means that the material is not replaced often when compared to other materials

Ongoing Research and Development

We continue to invest in advanced R & D projects, which provide improved properties in our copper-nickel alloys. Our R&D team continuously researches to ensure that we forge and manufacture the best possible quality of flanges, which meets but exceeds any industrial standards. This commitment to development guarantees Nexus Cupro Nickel is always on top of the complete flange manufacturing spectrum

Global Standards and Certifications

Our products adhere to global standards/ certifications; ASTM, ASME & ANSI. The Nexus Cupro Nickel branches boast manufacturing facilities that are ISO 9001:2015 certified; thus demonstrating our dedication to the purist and stringent quality management systems. We make sure that we not only meet international standards with every flange but also provide the certifications our clients need to trade globally and guarantee quality

Conclusion

At Nexus Cupro Nickel, we are committed to delivering top-notch copper-nickel forged flanges, backed by a deep understanding of metallurgy, precise manufacturing techniques, and stringent quality controls. Our expertise and dedication to quality ensure that our products provide unmatched performance in challenging environments, making us a trusted partner in various industries

Whether you are involved in the marine sector, chemical processing, or any industry requiring robust flange solutions, our team at Nexus Cupro Nickel is here to provide you with the best products and support. Join us in our journey to create sustainable and durable connections in your applications

You can Contact Nexus Cupro Nickel at sales@nexuspipefittings.com to discover more about Copper-Nickel Flanges and their industrial applications