CONDENSATE POT

Home / Tube Fittings / CONDENSATE POT

TUBE FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

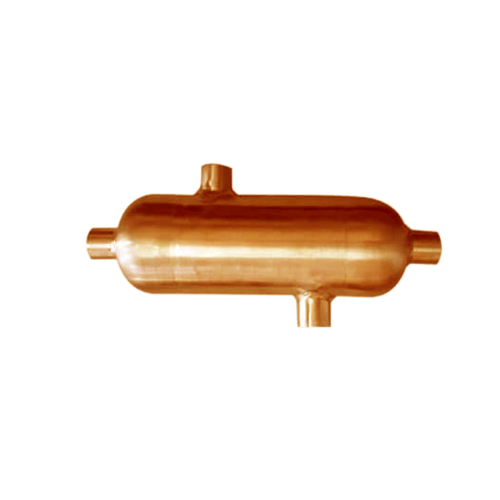

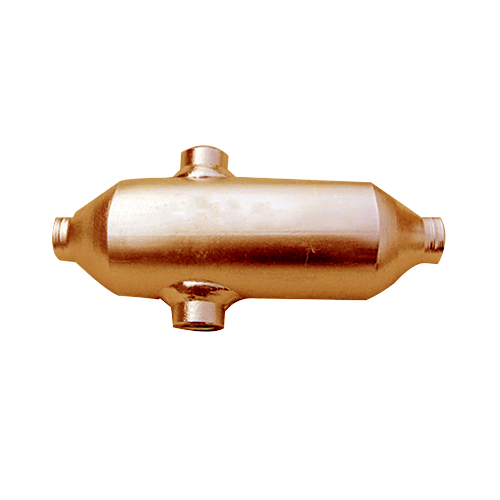

COPPER NICKEL CONDENSATE POT

Nexus Alloys and Steel, a reputable manufacturer and exporter, specializes in producing high-quality Condensate Pots. These essential components play a crucial role in various industrial applications, including petrochemicals, oil and gas, and chemical manufacturing. Nexus Alloys and Steel crafts their condensate pots using premium materials, particularly stainless steel. This choice ensures durability and resistance to corrosion, even in challenging environments.The company emphasizes selecting raw materials from trusted suppliers and thoroughly testing them to maintain top-notch quality. Condensate pots assist in managing pressure variations within industrial systems. By collecting and holding condensate, they prevent damage to sensitive equipment and maintain optimal system pressure.These pots contribute to system safety by preventing liquids from entering sensitive instruments or equipment. This reduces the risk of damage and ensures smooth operation.Thanks to their adaptable design and connection options, condensate pots can be easily installed in various systems, including steam lines and pipelines. By preventing liquid accumulation in critical components, condensate pots reduce the frequency of maintenance requirements, leading to extended equipment lifespan

DESCRIPTION

Nexus Alloys and Steels offer customization options, allowing clients to choose materials, sizes, and configurations that best fit their specific applications.Many pots come with transparent or removable covers, enabling easy visual inspection and monitoring of the condensate level and pot condition.Some designs include insulation to preserve the temperature of collected condensate, which is crucial for processes requiring specific fluid temperatures. Nexus Alloys and Steel offers copper-nickel condensate pots in various sizes and shapes, ensuring they meet the diverse needs of their clients

Key Features of Copper-Nickel Condensate Pot

- Maximizing Accuracy : The primary purpose of a condensate pot is to maximize the accuracy of differential pressure flow measurement, especially in steam (or vapor) applications. By using a condensate pot, we ensure that the condensation of steam in the impulse lines does not compromise the ability to accurately sense differential pressure fluctuations

- Eliminating Measurement Errors : Between the process tapping and the condensate pot, there exists steam vapor. However, between the condensate pot and the differential pressure transmitter, we have water (liquid). This arrangement eliminates any measurement errors arising from a liquid-vapor mix at the measurement device. To achieve this, both high-pressure (HP) and low-pressure (LP) impulse lines should be of equal length, thus minimizing pressure head errors

- Installation Considerations :

- Orientation : Condensate pots can be installed either vertically or horizontally between the primary flow meter and the secondary transmitter or gauge. They act as a barrier to the line fluid, allowing direct sensing of flow conditions

- Mounting Level : Mounting both condensate pots at the same level is crucial to minimize errors due to unequal fluid head in the connecting pressure lines.

- Impulse Line Length : Keep vapor impulse lines as short as possible

- Anti-Freeze Media : Consider adding an anti-freeze medium (such as glycol) to the water lines

- Blowdown Facility : It is recommended that both impulse lines from the condensate pot to the differential pressure measuring device include a facility for ‘blowdown.’ Regularly blowing down these lines prevents debris accumulation that could impact measurement accuracy

- Foreign Material Trapping : Condensate pots also serve to trap any foreign material from the pipeline, preventing damage to sensitive instrumentation components. The condensate is drained from the bottom valve connection, often using ball valves as the drain port

GRADES

- Copper-Nickel Alloy (C70600 - 90:10) : This grade contains 90% copper and 10% nickel. Known for its excellent resistance to seawater corrosion, making it suitable for marine applications. Often used in condensate pots due to its durability and anti-corrosive properties

- Copper-Nickel Alloy (C71500 - 70:30) : Composed of 70% copper and 30% nickel. Offers good strength, high ductility, and resistance to biofouling. Widely used in condensate pots for its robustness and resistance to erosion

- Monel :

- Monel 400 : A nickel-copper alloy with excellent corrosion resistance in various environments

- Monel K500 : Provides additional strength and hardness compared to Monel 400 Both Monel grades are suitable for condensate pots when measuring corrosive fluids

- Nickel Alloys :

- Nickel 200 : Pure nickel with exceptional resistance to various corrosive media

- Nickel 201 : Similar to Nickel 200 but with lower carbon content These nickel grades are used in condensate pots for their chemical stability

- Inconel Alloys :

- Inconel 600 : Resistant to high-temperature oxidation and corrosion

- Inconel 601 : Offers excellent mechanical properties at elevated temperatures

- Inconel 625 : Known for its strength and resistance to aggressive environments

- Inconel 718 : Combines high strength with corrosion resistance

TECHNICAL SPECIFICATION

- Material of Construction (MOC) : Carbon Steel, Stainless Steel (SS316L), Hastelloy, Monel, Inconel

- Design Temperature : Up to 350°C

- Hydro Shell Pressure : Can withstand pressures up to 200 bar

- Pipe Sizes Available : 2", 3", 4", and 8"

- Pipe Length : Ranges from 300mm to 4000mm

- Pipe Schedule : Available in 40, 80, 160, and XX Seamless pipe

- Mounting Position : Can be installed either vertically or horizontally

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports