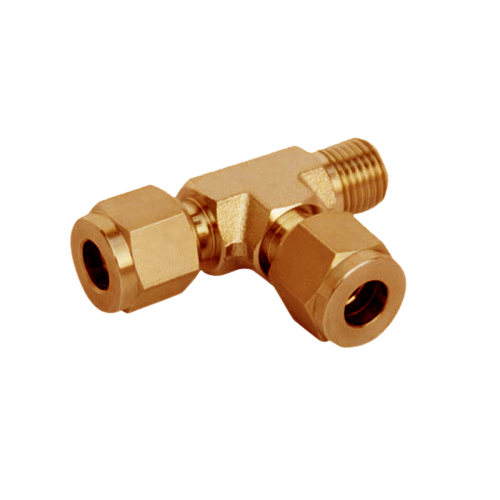

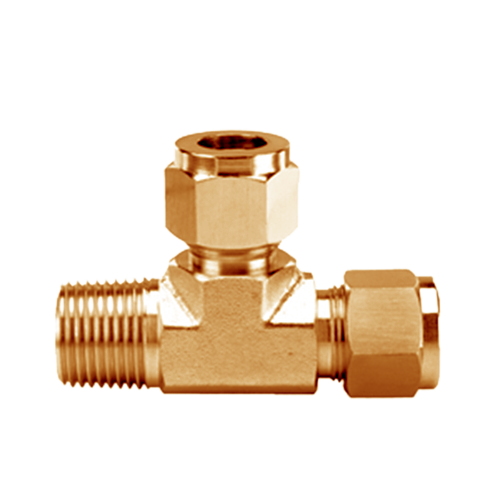

RUN-TEE

Home / Tube Fittings / RUN-TEE

TUBE FITTINGS

Products

Get a Free Quote

Toll Free Call :

+91 93216 51417

COPPER NICKEL RUN-TEE

The Copper Nickel Run-Tee, often referred to as a Cu-ni Female Run-Tee manufactured by Nexus Alloys and Steels, is a type of tube fitting used in various industrial applications. It’s made from Cupronickel, a copper-nickel alloy known for its exceptional properties. Cupronickel has excellent resistance to corrosion, crevice corrosion, stress corrosion cracking, and hydrogen embrittlement. It also exhibits distinct working features such as strength, weldability, and durability

DESCRIPTION

Cupro Nickel is offered in two grades: 90/10 Cupro-nickel and 70/30 Cupro-nickel, which are generated based on the amount of Copper and Nickel in the alloy. These fittings are made in a variety of materials, sizes, specifications, grades, and dimensions to fulfill the varying needs of various applications. Run-Tee offered by Nexus Alloys and Steels are popular industrial tube fittings that offer efficient pneumatic system connections. These tees ensure secure, leak-proof seals, resist corrosion, and perform well in tough environments. They come in various sizes and materials like stainless steel, Inconel, monel, and more, tailored to specific industries. In summary, Copper Nickel Run-Tees are versatile, durable, and reliable fittings used in a wide range of industrial applications

Key features Copper Nickel Run-Tees

- Material Composition : They are primarily composed of copper and nickel, with small amounts of other elements added to enhance properties such as strength, corrosion resistance, hardenability, weldability, and castability

- Types of Fittings : Copper Nickel Run-Tees come in various types such as Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories

- Sizes & Pressure Rating : They are available in sizes from 1/8’’ to 2’’ and 3mm to 50mm. The pressure rating varies from 1000 Psi, 3000 Psi, 6000 Psi, to 10000 Psi

- Threads : The threads can be NPT, BSPT, or BSPP

- High Tensile Strength : Copper Nickel Run-Tees have high tensile strength, which makes them robust and durable

- Customizability : The design of Run-Tees, diameter, thickness can be customized according to the requirements

- Mechanical Properties : Copper Nickel Run-Tees have a density of 8.1 g/cm3 and a yield strength (0.2%Offset) of Psi – 35,000, MPa – 2410

- Electrical Conductivity : Copper Nickel Run-Tees exhibit high electrical conductivity, making them suitable for electrical and electronic applications

GRADES

- Cu-Ni 90/10 (UNS C70600) : C70600, commonly referred to as Copper Nickel 90/10, is an alloy composed of 90% copper and 10% nickel, with the addition of iron and manganese to impart high strength and corrosion resistance. Widely utilized in marine applications, this alloy exhibits exceptional resistance to various environmental factors such as seawater, brine water, organic compounds, salts, diluted non-oxidizing acids, and more

- Cu-Ni 70/30 (UNS C71500) : C71500, known as Copper Nickel 70/30, consists of 70% copper and 30% nickel, along with small quantities of iron and manganese aimed at enhancing overall strength and corrosion resistance. Offering superior resistance to corrosion and erosion when compared to Copper Nickel 90/10, it finds application in demanding conditions in both marine and industrial services

TECHNICAL SPECIFICATION

- Material : Copper-Nickel

- Chemical Composition : Copper 88.6%, Nickel 10.0%, Iron 1.4%

- Mechanical Properties : Tensile strength is 45,000 psi, Yield strength is 18,000 psi, and Elongation is 35%

- Size : Available in sizes from 10 mm to 100 mm & 1/2” to 4”

- Standards : Conforms to MIL-T-16420K, Type I, Grade 1, ASTM B 466

SERVICES & CERTIFICATES

- Testing Facility Available Chemical Analysis, Mechanical Tests, Ultrasonic test, PMI test , Hydrostatic test, Radiography test, Corrosion test, Metallography Test, & Miscellaneous test

- Test Certificates : Manufacturer Test Certificates as per EN 10204 type 3.1 & 3.2 as well as NABL lab test reports